Canada Occupational Health and Safety Regulations (SOR/86-304)

Full Document:

- HTMLFull Document: Canada Occupational Health and Safety Regulations (Accessibility Buttons available) |

- XMLFull Document: Canada Occupational Health and Safety Regulations [914 KB] |

- PDFFull Document: Canada Occupational Health and Safety Regulations [1595 KB]

Regulations are current to 2024-11-26 and last amended on 2023-12-15. Previous Versions

SCHEDULE I(Sections 18.1 and 18.18)

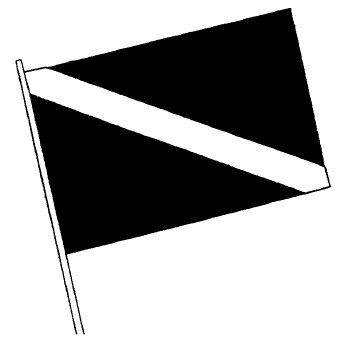

Diver’s Flag

Red rectangle with white diagonal stripe

- SOR/98-456, s. 1

- Date modified: