Cribs and Cradles Regulations

SOR/86-962

Registration 1986-09-11

Regulations Respecting the Advertising, Sale and Importation of Cribs and Cradles

P.C. 1986-2086 1986-09-11

Her Excellency the Governor General in Council, on the recommendation of the Minister of Consumer and Corporate Affairs, pursuant to section 7 of the Hazardous Products Act, is pleased hereby to revoke the Cradles and Cribs Regulations, C.R.C., c. 922 and to make the annexed Regulations respecting the advertising, sale and importation of cribs and cradles.

Short Title

1 These Regulations may be cited as the Cribs and Cradles Regulations.

Interpretation

2 In these Regulations,

- Act

Act means the Hazardous Products Act; (Loi)

- adjustment position

adjustment position means a position of a movable or move-away side in which the side latches or locks into position and from which the side cannot be moved without unlatching or unlocking the appropriate mechanism; (position d’ajustement)

- movable side

movable side, in respect of a standard or portable crib, means a side of a crib that

(a) has more than one adjustment position,

(b) has an upper surface that, in the case of a standard crib, does not move lower than 230 mm above and, in the case of a portable crib, does not move lower than 130 mm above, the upper surface of the mattress support in the highest position of the mattress support, and

(c) has a lower surface that does not move above the upper surface of the mattress support in the lowest position of the mattress support; (côté mobile)

- move-away side

move-away side, in respect of a standard or portable crib, means a side of a crib that has more than one adjustment position and that

(a) has an upper surface that moves lower than 230 mm above the upper surface of the mattress support in the highest position of the mattress support,

(b) has a lower surface that moves above the mattress support in the lowest position of the mattress support,

(c) moves sideways or rotates, in whole or in part, or

(d) detaches from the crib in the course of normal use, which detachment does not constitute disassembly, according to the manufacturer’s recommended instructions; (côté escamotable)

- portable crib

portable crib means a crib that weighs 10 kg or less and

(a) that may be easily carried by one person without requiring folding, collapsing or disassembly, or

(b) that may be easily carried by one person and may be folded or collapsed without being disassembled to occupy a volume substantially less than the volume it occupies when in use; (lit d’enfant portatif)

- product

product means a product included in item 25 of Part II of the schedule to the Act; (produit)

- side

side means the side, front or end of a product; (côté)

- slat

slat, in respect of a product, includes a corner post, bar, rod, panel or other similar component; (barreau)

- standard crib

standard crib means a crib that is not easily disassembled and not easily carried to another location. (lit d’enfant ordinaire)

- stationary side

stationary side, in respect of a standard or portable crib, means a side of a crib that has only one position. (côté fixe)

- SOR/88-560, s. 1

General

3 (1) A product may be advertised, sold or imported into Canada only if it meets the applicable requirements of these Regulations.

(2) No reference, direct or indirect, to the Act or these Regulations shall be made in any written material applied to or accompanying a product or in any advertisement of the product.

Labelling and Instructions

4 (1) Every product shall have indelibly printed on it or otherwise permanently affixed to it the following information, clearly and prominently displayed in letters and numerals not less than 2.5 mm in height:

(a) the name and principal place of business in Canada of the importer or of the person by or for whom the product is made, in either official language;

(b) the model name or model number of the product in either official language; and

(c) the year and month of manufacture of the product.

(2) Every container in which a product is sold shall have, indelibly printed on it or otherwise permanently affixed to it, the information required by paragraphs (1)(a) to (c).

(3) Every standard crib and every portable crib shall have indelibly printed on it or otherwise permanently affixed to it, in both official languages, the following warning statements, displayed in letters and numerals not less than 2.5 mm in height except for the title, “WARNING”, which shall be displayed in letters at least 5 mm in height:

“WARNING

Do not use this crib if the enclosed or attached instructions cannot be strictly adhered to. Do not use this crib if the child is able to climb out unaided or is taller than 90 cm. Do not place cords, straps or similar items that could become wound around the child’s neck in or near this crib. Ensure that the sides are properly latched or locked in place when the crib is occupied. The mattress used with this crib should not be more than 15 cm thick and should be of such length and width that the gap between the mattress and the sides of the crib is not more than 3 cm when the mattress is pushed into the corner of the crib.

MISE EN GARDE

Ne pas utiliser le lit d’enfant à moins d’être en mesure de respecter rigoureusement le mode d’emploi ci-joint ou apposé sur le produit. Ne pas utiliser le lit d’enfant si l’enfant est capable d’en sortir sans aide ou si l’enfant mesure plus de 90 cm. Ne pas mettre dans le lit, ou à proximité du lit, des cordes, courroies ou objets semblables qui pourraient s’enrouler autour du cou de l’enfant. S’assurer que les côtés sont bien enclenchés ou verrouillés lorsque l’enfant est placé dans le lit. L’épaisseur du matelas utilisé dans le lit ne doit pas être supérieure à 15 cm, et sa longueur et sa largeur doivent être telles que l’espace entre le matelas et les côtés du lit ne soit pas supérieur à 3 cm lorsque le matelas est poussé dans un des coins.”

(4) Every cradle shall have indelibly printed on it or otherwise permanently affixed to it, in both official languages, the following warning statements, displayed in letters and numerals not less than 2.5 mm in height except for the title, “WARNING”, which shall be displayed in letters at least 5 mm in height:

“WARNING

Do not use this cradle if the enclosed or attached instructions cannot be strictly adhered to. Do not use this cradle if the child is able to climb out unaided. Do not place cords, straps or similar items that could become wound around the child’s neck in or near this cradle. The mattress used with this cradle should not be more than 8 cm thick and should be of such length and width that the gap between the mattress and the sides of the cradle is not more that 3 cm when the mattress is pushed into one corner of the cradle.

MISE EN GARDE

Ne pas utiliser le berceau à moins d’être en mesure de respecter rigoureusement le mode d’emploi ci-joint ou apposé sur le produit. Ne pas utiliser le berceau si l’enfant est capable d’en sortir sans aide. Ne pas mettre dans le berceau, ou à proximité du berceau, des cordes, courroies ou objets semblables qui pourraient s’enrouler autour du cou de l’enfant. L’épaisseur du matelas utilisé dans le berceau ne doit pas être supérieure à 8 cm, et sa longueur et sa largeur doivent être telles que l’espace entre le matelas et les côtés du berceau ne soit pas supérieur à 3 cm lorsque le matelas est poussé dans un des coins.”

(5) Every product shall have indelibly printed on it, or have in a pouch that is permanently affixed to it, instructions and warnings that clearly state, in both official languages, the following information, with line drawings or photographs illustrating the sequence of steps where needed:

(a) how the product is to be assembled, if the product is sold not fully assembled;

(b) how the product is to be folded and unfolded, if the product is capable of being folded;

(c) how to adjust the height of the mattress support, if the height can be adjusted;

(d) a list of parts; and

(e) a warning stating that parents should ensure a safe environment for the child by checking regularly, before placing the child in the product, that every component is properly and securely in place.

(6) In addition to subsections (3) and (4), every product shall have, permanently affixed to it, a pouch in which the applicable warning set out in subsection (3) or (4) is contained.

(7) Every move-away side shall have indelibly printed on it or otherwise permanently affixed to it, in both official languages, a warning statement, clearly and prominently displayed in letters not less than 2.5 mm in height except for the title, “WARNING”, which shall be displayed in letters at least 9 mm in height, that the child never be left unattended when the move-away side is not in the vertical position designed to provide sleeping accommodation for an unattended child.

- SOR/88-560, s. 2

General and Performance Requirements

5 No standard crib or cradle shall have any of its mattress support mechanisms deform permanently or disengage or have its mattress support dislodge when tested in accordance with Schedule I.

6 (1) Every latching or locking mechanism of a movable side other than a mattress support mechanism, shall

(a) require two separate positive and simultaneous actions on the part of the user to release the mechanism; and

(b) engage automatically.

(2) Every move-away side shall have

(a) at least two of the latching or locking mechanisms that meet the requirements of subsection (1); and

(b) two latching or locking mechanisms that engage automatically where each latching or locking mechanism requires

(i) a force of 35 N to disengage the mechanism where disengagement occurs as a result of a pull or push force applied to the mechanism; or

(ii) a torque of 0.8 N.m to disengage the mechanism where disengagement occurs as a result of a turning force applied to the mechanism.

- SOR/88-560, s. 3

7 Every product that rocks or swings shall be so designed as to prevent the product from rocking or swinging beyond a 20° angle from the vertical.

8 (1) The distance above the upper surface of the mattress support in its lowest position to the upper surface of the lowest stationary side shall be,

(a) in the case of a standard crib, not less than 660 mm; and

(b) in the case of a portable crib, not less than 560 mm.

(2) Every movable and move-away side shall have at least one adjustment position in which the distance above the upper surface of the mattress support in the lowest position of the mattress support to the upper surface of the movable or move-away side shall be,

(a) in the case of a standard crib, not less than 660 mm; and

(b) in the case of a portable crib, not less than 560 mm.

(3) Every stationary or movable side shall, in every adjustment position, have its lowest surface below the upper surface of the mattress support in the lowest position of the mattress support.

(4) Every move-away side, when in a position which meets the requirements of subsection (2), shall have its lowest surface of the move-away side below the upper surface of the mattress support in the lowest position of the mattress support.

(5) Where the lowest surface of a move-away side is in the lowest adjustment position above the upper surface of the mattress support in the highest adjustment position of the mattress support, the distance above the upper surface of the mattress support to the lowest surface of the move-away side shall be not less than 360 mm.

- SOR/88-560, s. 4

9 (1) The distance above the upper surface of the mattress support in its highest position to the upper surface of the lowest stationary side, or the upper surface of the movable side that has the lowest adjustment position, in the lowest adjustment position of the movable side, shall be

(a) in the case of a standard crib, not less than 230 mm; and

(b) in the case of a portable crib, not less than 130 mm.

(2) The upper surface of a move-away side shall, in every adjustment position, be

(a) below the upper surface of the mattress support in the lowest position of the mattress support; or

(b) in the case of

(i) a standard crib, not less than 230 mm above the upper surface of the mattress support in the highest position of the mattress support, and

(ii) a portable crib, not less than 130 mm above the upper surface of the mattress support in the highest position of the mattress support.

(3) Every move-away side shall have one adjustment position that is

(a) at least 150 mm below the adjustment position described in subsection 8(2); and

(b) not less than, in the case of a standard crib, 230 mm above and, in the case of a portable crib, 130 mm above, the upper surface of the mattress support in the highest position of the mattress support.

- SOR/88-560, s. 4

10 In any advertisement for a standard or portable crib with a movable or move-away side that depicts a child in the crib,

(a) the upper surface of the lowest side in the highest adjustment position of the lowest side shall be, in the case of a standard crib, not less than 660 mm above, and, in the case of a portable crib, not less than 560 mm above, the upper surface of the mattress support in the lowest position of the mattress support;

(b) the lower surface of any side shall not be in an adjustment position higher than the upper surface of the mattress support in the lowest position of the mattress support; and

(c) the sides shall be in the adjustment position designed to provide sleeping accommodation for an unattended child.

- SOR/88-560, s. 4

11 In a product, no space

(a) between a slat and any adjacent slat, and

(b) in any component above the upper surface of the mattress support in its lowest position

shall permit the passage of a solid rectangular block measuring 60 × 100 × 100 mm in any orientation through the space when tested in accordance with Schedule II.

12 Every corner post in a standard crib or portable crib shall be designed in such a manner that no part of the corner post protrudes more than 3 mm above the upper surface of the highest side of the crib when measured from the lowest point on the upper surface of that side within 70 mm from the centre line of the corner post.

13 No standard crib or portable crib shall be contoured in any way that, or have any projections, attachments or mechanisms above the upper surface of the mattress support that, could result in the occupant’s clothing becoming entangled therewith.

14 The size of the openings in any mesh on a product shall meet the requirements of subsections 5(1) and (2) of the Playpens Regulations.

15 Any mattress supplied with a product

(a) shall not be more than 30 mm shorter and 30 mm narrower than the respective interior dimensions of the product;

(b) shall not be more than

(i) 150 mm in thickness, where the product is a standard crib or portable crib, or

(ii) 80 mm in thickness, where the product is a cradle; and

(c) shall be stitched using lock-stitching.

16 No standard crib or cradle shall have any visible signs of damage, disengagement or deformation when tested in accordance with Schedule III.

17 Every component of a product that is small enough to be placed in a small parts cylinder of the type described in Schedule IV shall be so fitted or affixed to the product that the component will not become detached from the product when subjected to a force of 90 N applied in any direction.

- SOR/2004-65, s. 12

18 No slat of a standard crib or portable crib shall turn, disengage, deform, deflect or become damaged when tested in accordance with Schedule V.

19 A product shall be so designed and constructed as to preclude injury from shearing or pinching to infants and children.

20 (1) Every exposed metal part of a product shall be free of burrs or sharp edges, corners, points or projections.

(2) Every cut edge of the metal tubing of a product that is accessible to an occupant of the product shall be smoothly finished to eliminate rough or sharp edges, corners or points or shall be protected by a cap that will remain in place when subjected to a force of 90 N applied in any direction.

(3) Every exposed wooden or plastic part or part of a similar hard material of a product shall be smoothly finished to eliminate rough or sharp edges, corners and points and be free from splits, cracks or other defects.

(4) The threaded end of every bolt of a product that is accessible to an occupant of the product shall be protected by an acorn nut or other suitable device.

21 Every open hole in a metal, plastic or wooden component or in a component of a similar hard material of a product that is accessible to an occupant of the product

(a) shall be of such size or shape that if it admits a rod 5.5 mm in diameter it will also admit a rod 10 mm in diameter; or

(b) if the minor dimension of the hole is between 5.5 and 10 mm, shall have a depth that is not greater than the minor dimension.

22 Every coil spring accessible to the occupant of a product shall be covered or otherwise designed to prevent injuries.

23 No product shall have applied to it a decorative or protective coating that contains any of the following substances:

(a) lead pigments;

(b) more than 0.5 per cent weight to weight of lead in the total solids contained in such coating;

(c) any compound of antimony, arsenic, cadmium, selenium or barium introduced as such if more than one-tenth of one per cent of such compound dissolves in five per cent hydrochloric acid after stirring for ten minutes at twenty degrees Celsius; or

(d) any compound of mercury introduced as such.

24 No component of a product made in whole or in part of a textile fibre shall, when tested in accordance with method D1230-61, the Standard Method of Test for Flammability of Clothing Textiles, a standard of the American Society for Testing and Materials, have a time of flame spread of

(a) 7 seconds or less, where the component does not have a raised fibre surface; or

(b) 7 seconds or less, where the component has a raised fibre surface and exhibits ignition or fusion of its base fibres.

SCHEDULE I(Section 5)Test for Mattress Support System

1 The method to be used for testing the mattress support system of a standard crib or cradle is as follows:

(a) omitting accessories that could hinder the implementation of the test, assemble the crib or cradle according to the manufacturer’s recommended instructions;

(b) secure the crib or cradle to a horizontal surface in a manner that does not impede the test;

(c) apply and maintain for one minute an upward force at one corner of the mattress support, within 150 mm of the two sides forming the corner, such that a force of 250 N is applied on the mattress support mechanism;

(d) note any dislodging of the mattress support or disengagement or deformation of any mattress support mechanism;

(e) repeat (c) and (d) at the other corners of the mattress support;

(f) apply and maintain for one minute an upward force, as close as possible to each corner of the mattress support, such that a force of 250 N is applied simultaneously to each mattress support mechanism;

(g) note any dislodging of the mattress support or disengagement or deformation of any mattress support mechanism;

(h) apply a force of 200 N on one of the mattress support mechanisms in a manner that will facilitate disengaging the mattress support mechanism;

(i) note any dislodging of the mattress support or disengagement or deformation of any mattress support mechanism;

(j) repeat (h) and (i) on the remaining mattress support mechanisms;

(k) apply a force of 200 N in any direction and at any point on one of the mattress support mechanism in a manner that could cause a deformation of the mechanism or any component thereof;

(l) note any dislodging of the mattress support or disengagement or deformation of any mattress support mechanism; and

(m) repeat (k) and (l) on the remaining mattress support mechanisms.

SCHEDULE II(Section 11)Test for Spacing Between Slats

1 The method to be used for testing the spacing between the slats of a product is as follows:

(a) assemble the product according to the manufacturer’s recommended instructions;

(b) if the mattress support is adjustable, adjust the mattress support to its lowest position;

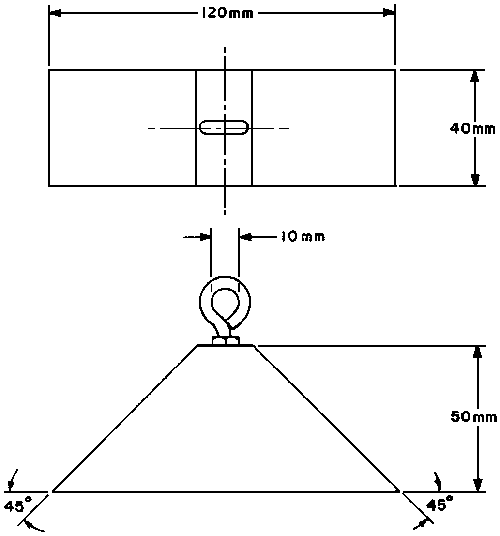

(c) place a right triangular prism-shaped metallic loading wedge, of the design and dimensions shown in Figure 1, in the space between a slat and any adjacent slat of the product midway along the greatest dimension of the space;

(d) apply a pull of 90 N and maintain the force for 10 seconds on the eye-bolt of the loading wedge in a direction perpendicular to a plane passing through the points of contact of the wedge with the two components;

(e) attempt to pass, without forcing, a solid rectangular block measuring 60 × 100 × 100 mm through the space, anywhere above or below the loading wedge;

(f) repeat (e) with the block in different orientations; and

(g) repeat (c) to (f) for all other spaces between other slats and adjacent slats.

FIGURE 1

SCHEDULE III(Section 16)Tests for Structural Integrity

1 The method to be used for testing the structural integrity of a standard crib under dynamic conditions is as follows:

(a) assemble the crib according to the manufacturer’s recommended instructions;

(b) secure the crib to a horizontal surface in a manner that does not impede the test;

(c) place on the mattress support a 100 mm thick sheet of polyurethane foam having a density of 30 kg/m3, a 25% indentation load deflection (ILD) of 144 N and a length, width and thickness that meet the requirements of paragraphs 15(a) and (b);

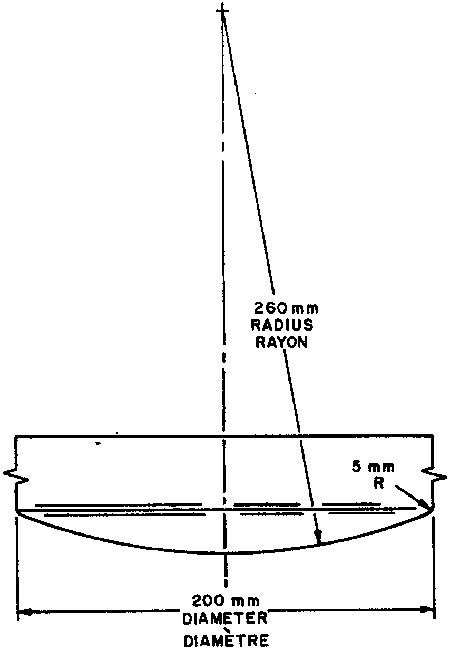

(d) using a 20 kg test load, 200 mm in diameter, with a 260 mm bottom curvature and with cambered edges, of the design and dimensions shown in Figure 2, allow the test load to fall freely from a height of 150 mm 150 times at a rate of one impact per second at the geometric centre of the upper surface of the polyurethane foam, in such a manner that the upper surface of the load remains parallel to the horizontal surface referred to in paragraph (b);

(e) note any visible signs of damage to the crib, any disengagement or deformation of any latching or locking mechanism or any lossening of any screw or fastening;

(f) repeat (d) and (e) at each corner of the mattress support such that the centre of the test load is 150 mm from the two sides forming the corners; and

(g) repeat (d) and (e) at the mid-point along the edge of the mattress support on all adjustable sides of the product such that the test load is 150 mm from those sides.

2 The method to be used for testing the structural integrity of a cradle under dynamic conditions is as follows:

(a) assemble the cradle according to the manufacturer’s recommended instructions;

(b) secure the cradle to a horizontal surface in a manner that does not impede the test;

(c) place on the mattress support a mattress having the length, width and thickness required by subsections 15(a) and (b);

(d) using a 13.7 kg test load having a square contact area of 929 cm2, allow the test load to fall freely from a height of 150 mm 500 times at a rate of one impact per second at the geometric centre of the upper surface of the mattress; and

(e) note any visible signs of damage to the cradle or disengagement or deformation of any latching or locking mechanism.

3 The method to be used for testing the structural integrity of a standard crib under horizontal force conditions is as follows:

(a) assemble the crib according to the manufacturer’s recommended instructions;

(b) secure the crib to a horizontal surface in a manner that does not impede the test;

(c) with the adjustable side or sides of the crib in the fully raised position, if the crib has an adjustable side or sides, apply an alternating horizontal force of 120 N in the transverse direction on the top of one side, at the mid-point, not more than 50 mm from the top of the side being tested, at a frequency of no less than 150 cycles per minute for a total of 9 000 cycles;

(d) note any visible signs of damage to the crib or disengagement or deformation of any latching or locking mechanism; and

(e) repeat (c) and (d) for the remaining sides of the crib.

4 The method to be used for testing the structural integrity of a standard crib under vertical force conditions is as follows:

(a) assemble the crib according to the manufacturer’s recommended instructions;

(b) secure the crib to a horizontal surface in a manner that does not impede the test;

(c) with the adjustable side or sides of the crib in the fully raised position, if the crib has an adjustable side or sides, apply an alternating vertical force of 120 N on the top of one side at a frequency of no less than 150 cycles per minute for a total of 9 000 cycles;

(d) note any visible signs of damage to the crib or disengagement or deformation of any latching or locking mechanism; and

(e) repeat (c) and (d) for the remaining sides of the crib.

FIGURE 2

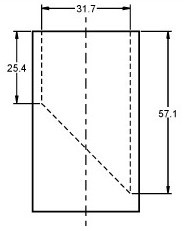

SCHEDULE IV(Section 17)Small Parts Cylinder

1 A small parts cylinder of the design and dimensions shown in Figure 3 shall be used for the purpose of measuring components referred to in section 17.

Notes:

– Not to scale

– All dimensions in mm

FIGURE 3

- SOR/2004-65, s. 13

SCHEDULE V(Section 18)Test for Slat Strength

1 The method to be used for testing the strength of a slat of a standard crib or portable crib is as follows:

(a) assemble the crib according to the manufacturer’s recommended instructions;

(b) secure the crib to a horizontal surface in a manner that does not impede the test;

(c) apply a torque of 8 N.m (newton metres) and maintain the force for 10 seconds on one of the slats;

(d) note any damage, turning or disengaging of the slat;

(e) repeat (c) and (d) with all other slats;

(f) apply a vertical upward force of 500 N and maintain the force for 30 seconds at the middle of the top rail on one of the sides of the crib with slats;

(g) note any damage or disengagement of any of the slats from the top rail; and

(h) repeat (f) and (g) on the remaining sides that have slats.

- Date modified: