Cribs, Cradles and Bassinets Regulations

SOR/2010-261

CANADA CONSUMER PRODUCT SAFETY ACT

Registration 2010-11-18

Cribs, Cradles and Bassinets Regulations

P.C. 2010-1412 2010-11-18

His Excellency the Governor General in Council, on the recommendation of the Minister of Health, pursuant to section 5Footnote a of the Hazardous Products ActFootnote b, hereby makes the annexed Cribs, Cradles and Bassinets Regulations.

Return to footnote aS.C. 2004, c. 9, s. 2

Return to footnote bR.S., c. H-3

Interpretation

Marginal note:Definitions

1 The following definitions apply in these Regulations.

Act

Loi

Act means the Hazardous Products Act. (Loi)

adjustment position

position de réglage

adjustment position means a position of a movable side in which the side latches or locks and from which the side cannot be moved without being unlatched or unlocked. (position de réglage)

bassinet

moïse

bassinet means a product whose primary function is to provide sleeping accommodation for a child, that includes sides to confine the occupant and that has a sleeping surface area that is less than or equal to 4 000 cm2. (moïse)

cradle

berceau

cradle means a product whose primary function is to provide sleeping accommodation for a child, that includes sides to confine the occupant and that has a sleeping surface area that is greater than 4 000 cm2 but less than or equal to 5 500 cm2. (berceau)

crib

lit d’enfant

crib means a product whose primary function is to provide sleeping accommodation for a child, that includes sides to confine the occupant and that has a sleeping surface area that is greater than 5 500 cm2. (lit d’enfant)

movable side

côté mobile

movable side means a side of a crib or cradle that has one or more adjustment positions. It includes a folding side, a move-downward side, a move-upward side, a move-sideways side and a rotating side. (côté mobile)

move-upward side

côté relevable

move-upward side means a movable side of a crib or cradle all or part of which can be moved upward. (côté relevable)

move-downward side

côté abaissable

move-downward side means a movable side of a crib or cradle all or part of which can be moved downward. (côté abaissable)

move-sideways side

côté à glissement latéral

move-sideways side means a movable side of a crib or cradle all or part of which can be moved sideways. (côté à glissement latéral)

person responsible

responsable

person responsible means

(a) in the case of a crib, cradle or bassinet that is manufactured in Canada, the manufacturer who sells it or advertises it; and

(b) in the case of a crib, cradle or bassinet that is imported, the importer. (responsable)

rotating side

côté pivotant

rotating side means a movable side of a crib or cradle all or part of which can be rotated around a vertical or horizontal axis. (côté pivotant)

slat

barreau

slat includes a post, bar, rod or other similar part of a crib, cradle or bassinet. (barreau)

stationary side

côté fixe

stationary side means a side of a crib, cradle or bassinet that has no adjustment positions. (côté fixe)

Authorization

Marginal note:Advertise, sell or import

2 A crib, cradle or bassinet may be advertised, sold or imported if it meets the requirements of these Regulations.

Information and Advertising

General Provisions

Marginal note:Reference to Act or Regulations

3 Information that appears on or that accompanies a crib, cradle or bassinet, and any advertisement of a crib, cradle or bassinet, must not make any direct or indirect reference to the Act or these Regulations.

Marginal note:Advertising

4 In any advertisement showing a crib or cradle that is occupied by a child, the movable side of the crib or cradle must be shown in the adjustment position designed to provide accommodation for an unattended child.

Presentation of Information

Marginal note:Requirements

5 The information required by these Regulations must meet all of the following requirements:

(a) be displayed prominently in both official languages;

(b) be printed on the crib, cradle or bassinet, or on a label that is permanently affixed to it;

(c) be printed in letters in a colour that contrasts sharply with the background; and

(d) be set out in a manner that is clear and legible and sufficiently durable to remain legible throughout the useful life of the crib, cradle or bassinet under normal conditions of transportation, storage, sale and use.

Marginal note:Print

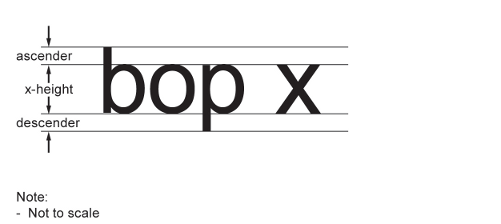

6 (1) The information must be printed in a standard sans-serif type that

(a) is not compressed, expanded or decorative; and

(b) has a large “x-Height” relative to the ascender or descender of the type, as illustrated in Figure 1 of Schedule 1.

Marginal note:Height of type

(2) The height of the type is determined by measuring an upper-case letter or a lower-case letter that has an ascender or a descender, such as “b” or “p”.

Marginal note:Signal words — characteristics

7 (1) The signal words “WARNING” and “MISE EN GARDE” must be displayed in boldfaced, upper-case type not less than 5 mm in height.

Marginal note:Other information — height

(2) All other information must be displayed in type not less than 2.5 mm in height.

Cribs, Cradles and Bassinets

Marginal note:Required information

8 The following information must appear on every crib, cradle and bassinet, as well as on any packaging in which one is displayed to the consumer:

(a) the name and principal place of business in Canada of the person responsible;

(b) its model name or model number; and

(c) the expression “DATE:” followed immediately by words or numerals that indicate when it was manufactured, consisting of the year and either the month or week, listed in that order.

Marginal note:Assembly and use

9 (1) The following information must be set out on every crib, cradle and bassinet, including any drawings or photographs that are necessary to illustrate the sequence of steps:

(a) instructions on how to assemble it and a quantitative list of its parts, if it is sold not fully assembled;

(b) instructions on how to fold and unfold it, if it can be folded;

(c) instructions on how to adjust the height of the mattress support, if the height is adjustable; and

(d) a warning stating that caregivers must ensure that the crib, cradle or bassinet is safe by checking regularly, before placing the child in it, that every part is properly and securely in place.

Marginal note:Warning — pouches

(2) Despite paragraph 5(b), the information required by subsection (1) may be contained in or on a pouch that is permanently affixed to the crib, cradle or bassinet if the relevant warning set out in section 10, 11 or 12 is provided with that information.

Cribs

Marginal note:Warning — cribs

10 The following warning, or wording that conveys the same messages, must appear on every crib:

WARNING

- •Do not use this crib if you cannot exactly follow the accompanying instructions.

- •Do not use this crib for a child who can climb out of it or who is taller than 90 cm.

- •Do not place in or near this crib any cord, strap or similar item that could become wrapped around a child’s neck.

- •Do not place this crib near a window or a patio door where a child could reach the cord of a blind or curtain and be strangled.

- •Ensure that the sides of this crib are properly latched or locked in the appropriate position when a child is left unattended in it.

- •Check this crib regularly before using it and do not use it if any parts are loose or missing or if there are any signs of damage. Do not substitute parts. Contact the manufacturer if replacement parts or additional instructions are needed.

- •Use a crib mattress that is no thicker than 15 cm and is of such a size that, when it is pushed firmly against any side of the crib, it does not leave a gap of more than 3 cm between the mattress and any part of the sides of the crib.

- •Children can suffocate on soft bedding. Do not place pillows, comforters or soft mattresses in this crib.

MISE EN GARDE

- •Ne pas utiliser le lit à moins d’être en mesure de suivre précisément les instructions qui l’accompagnent.

- •Ne pas utiliser le lit si l’enfant est capable d’en sortir ou mesure plus de 90 cm.

- •Ne pas mettre dans le lit ou à proximité de celui-ci des cordes, courroies ou objets semblables qui risqueraient de s’enrouler autour du cou de l’enfant.

- •Ne pas placer le lit près d’une fenêtre ou d’une porte-fenêtre où l’enfant pourrait se saisir des cordes d’un store ou d’un rideau et s’étrangler.

- •S’assurer que les côtés du lit, dans le cas où l’enfant y est laissé sans surveillance, sont bien enclenchés ou verrouillés à la position appropriée.

- •Vérifier régulièrement le lit préalablement à son utilisation et ne pas l’utiliser en cas de détection d’une pièce desserrée, de pièce manquante ou de tout signe de dommages. Ne pas substituer une pièce à une autre. Communiquer avec le fabricant pour obtenir, au besoin, une pièce de rechange ou des instructions supplémentaires.

- •Utiliser un matelas pour lit d’enfant dont l’épaisseur est d’au plus 15 cm et dont la superficie permet d’empêcher, lorsqu’il est poussé fermement contre un côté quelconque du lit, qu’un espace de plus de 3 cm soit créé entre le matelas et une partie quelconque de tout côté.

- •L’enfant peut s’étouffer en présence d’articles de literie mous. Ne pas mettre dans le lit d’oreiller, d’édredon ou de matelas mou.

Cradles

Marginal note:Warning — cradles

11 The following warning, or wording that conveys the same messages, must appear on every cradle:

WARNING

- •Do not use this cradle if you cannot exactly follow the accompanying instructions.

- •Do not use this cradle for a child who can push up on their hands and knees or who has reached the manufacturer’s recommended weight limit.

- •Do not place in or near this cradle any cord, strap or similar item that could become wrapped around a child’s neck.

- •Do not place this cradle near a window or a patio door where a child could reach the cord of a blind or curtain and be strangled.

- •Ensure that the sides of this cradle are properly latched or locked in the appropriate position when a child is left unattended in it.

- •Check this cradle regularly before using it and do not use it if any parts are loose or missing or if there are any signs of damage. Do not substitute parts. Contact the manufacturer if replacement parts or additional instructions are needed.

- •Use a cradle mattress that is no thicker than 3.8 cm and is of such a size that, when it is pushed firmly against any side of the cradle, it does not leave a gap of more than 3 cm between the mattress and any part of the sides of the cradle.

- •Children can suffocate on soft bedding. Do not place pillows, comforters or soft mattresses in this cradle.

MISE EN GARDE

- •Ne pas utiliser le berceau à moins d’être en mesure de suivre précisément les instructions qui l’accompagnent.

- •Ne pas utiliser le berceau si l’enfant est capable de se mettre à quatre pattes ou a atteint le poids maximal recommandé par le fabricant.

- •Ne pas mettre dans le berceau ou à proximité de celui-ci des cordes, courroies ou objets semblables qui risqueraient de s’enrouler autour du cou de l’enfant.

- •Ne pas placer le berceau près d’une fenêtre ou d’une porte-fenêtre où l’enfant pourrait se saisir des cordes d’un store ou d’un rideau et s’étrangler.

- •S’assurer que les côtés du berceau, dans le cas où l’enfant y est laissé sans surveillance, sont bien enclenchés ou verrouillés à la position appropriée.

- •Vérifier régulièrement le berceau préalablement à son utilisation et ne pas l’utiliser en cas de détection d’une pièce desserrée, de pièce manquante ou de tout signe de dommages. Ne pas substituer une pièce à une autre. Communiquer avec le fabricant pour obtenir, au besoin, une pièce de rechange ou des instructions supplémentaires.

- •Utiliser un matelas pour berceau dont l’épaisseur est d’au plus 3,8 cm et dont la superficie permet d’empêcher, lorsqu’il est poussé fermement contre un côté quelconque du berceau, qu’un espace de plus de 3 cm soit créé entre le matelas et une partie quelconque de tout côté.

- •L’enfant peut s’étouffer en présence d’articles de literie mous. Ne pas mettre dans le berceau d’oreiller, d’édredon ou de matelas mou.

Bassinets

Marginal note:Warning — bassinets

12 The following warning, or wording that conveys the same messages, must appear on every bassinet:

WARNING

- •Do not use this bassinet if you cannot exactly follow the accompanying instructions.

- •Do not use this bassinet for a child who can roll over or who has reached the manufacturer’s recommended weight limit.

- •Do not place in or near this bassinet any cord, strap or similar item that could become wrapped around a child’s neck.

- •Do not place this bassinet near a window or a patio door where a child could reach the cord of a blind or curtain and be strangled.

- •Check this bassinet regularly before using it and do not use it if any parts are loose or missing or if there are any signs of damage. Do not substitute parts. Contact the manufacturer if replacement parts or additional instructions are needed.

- •Use a bassinet mattress that is no thicker than 3.8 cm and is of such a size that, when it is pushed firmly against any side of the bassinet, it does not leave a gap of more than 3 cm between the mattress and any part of the sides of the bassinet.

- •Children can suffocate on soft bedding. Do not place pillows, comforters or soft mattresses in this bassinet.

MISE EN GARDE

- •Ne pas utiliser le moïse à moins d’être en mesure de suivre précisément les instructions qui l’accompagnent.

- •Ne pas utiliser le moïse si l’enfant est capable de se retourner ou a atteint le poids maximal recommandé par le fabricant.

- •Ne pas mettre dans le moïse ou à proximité de celui-ci des cordes, courroies ou objets semblables qui risqueraient de s’enrouler autour du cou de l’enfant.

- •Ne pas placer le moïse près d’une fenêtre ou d’une porte-fenêtre où l’enfant pourrait se saisir des cordes d’un store ou d’un rideau et s’étrangler.

- •Vérifier régulièrement le moïse préalablement à son utilisation et ne pas l’utiliser en cas de détection d’une pièce desserrée, de pièce manquante ou de tout signe de dommages. Ne pas substituer une pièce à une autre. Communiquer avec le fabricant pour obtenir, au besoin, une pièce de rechange ou des instructions supplémentaires.

- •Utiliser un matelas pour moïse dont l’épaisseur est d’au plus 3,8 cm et dont la superficie permet d’empêcher, lorsqu’il est poussé fermement contre un côté quelconque du moïse, qu’un espace de plus de 3 cm soit créé entre le matelas et une partie quelconque de tout côté.

- •L’enfant peut s’étouffer en présence d’articles de literie mous. Ne pas mettre dans le moïse d’oreiller, d’édredon ou de matelas mou.

Construction and Performance Standards

General Provisions

Marginal note:Shearing and pinching

13 Every crib, cradle and bassinet must be constructed so as to prevent injury to a child from shearing or pinching.

Marginal note:Coatings

14 Every crib, cradle and bassinet must be free from any surface coating that contains any of the following substances:

(a) total lead in excess of 90 mg/kg;

(b) any compound of antimony, arsenic, cadmium, selenium or barium if more than 0.1% of the compound dissolves in 5% hydrochloric acid after being stirred for 10 minutes at 20°C; or

(c) any compound of mercury.

Marginal note:Rocking or swinging

15 Every crib, cradle and bassinet that rocks or swings must be constructed so that it cannot rock or swing beyond a 20° angle from the vertical.

Marginal note:Strength and solidity of slats

16 A slat of a crib, cradle or bassinet must not turn, dislodge, deform or become damaged when tested in accordance with Schedule 2.

Marginal note:Openings

17 A completely bounded opening that is located above the mattress support of a crib, cradle or bassinet when the mattress support is in any position must not permit the passage of a solid rectangular block with dimensions of 60 mm × 100 mm × 100 mm in any orientation, when tested in accordance with Schedule 3.

Marginal note:Flammability

18 A component of a crib, cradle or bassinet that contains textile fibres or any other pliable material must not, when tested in accordance with the Canadian General Standards Board standard CAN/CGSB-4.2, No. 27.5-2008, entitled Textile Test Methods — Flame Resistance — 45° Angle Test — One Second Flame Impingement, have a time of flame spread of seven seconds or less if the component either

(a) does not have a raised fibre surface; or

(b) has a raised fibre surface and exhibits ignition or fusion of its base fibres.

Marginal note:Mesh — size of openings

19 (1) The openings in any mesh on a crib, cradle or bassinet must be of such a size that, when tested in accordance with Schedule 4, the tip of the probe illustrated in Figure 1 of that Schedule is unable to pass through them.

Marginal note:Mesh — strength and integrity

(2) Any mesh that forms part of the sides or bottom of a crib, cradle or bassinet must not, when tested in accordance with Schedule 5, either

(a) break or rupture; or

(b) become separated from its supporting structure or attachments.

Marginal note:Mattress

20 A mattress that is supplied with a crib, cradle or bassinet must

(a) be not more than

(i) 150 mm thick, in the case of a crib, or

(ii) 38 mm thick, in the case of a cradle or bassinet;

(b) be of such a size that, when it is pushed firmly against any side of the crib, cradle or bassinet, it does not leave a gap of more than 30 mm between the mattress and any part of the sides of the crib, cradle or bassinet; and

(c) be stitched using lock-stitching.

Marginal note:Entanglement

21 A crib, cradle or bassinet must not have any projection, attachment or mechanism located above the upper surface of the mattress support, when the mattress support is in any position, with which the clothing or any other object worn by the occupant could become entangled.

Marginal note:Wood, plastic or similar hard material

22 (1) Every exposed part of a crib, cradle or bassinet that is made of wood, plastic or a similar hard material must be smoothly finished to eliminate sharp edges, corners and points and must be free from splits, cracks and other defects.

Marginal note:Metal

(2) Every exposed part of a crib, cradle or bassinet that is made of metal must be smoothly finished and must be free from sharp edges, corners, points and projections.

Marginal note:Metal tubing

(3) Every cut edge of any metal tubing that is accessible to the occupant of a crib, cradle or bassinet must be either

(a) smoothly finished to eliminate sharp edges, corners and points; or

(b) protected by a cap that remains in place when subjected to a force of 90 N applied in any direction.

Marginal note:Bolts

(4) The threaded end of every bolt that is accessible to the occupant of a crib, cradle or bassinet must be protected by an acorn nut or an equally effective device.

Marginal note:Small parts

23 Every part of a crib, cradle or bassinet that is small enough to be totally enclosed in a small parts cylinder illustrated in Figure 1 of Schedule 6 must be affixed to the crib, cradle or bassinet so that the part does not become detached when subjected to a force of 90 N applied in any direction.

Marginal note:Coil springs

24 Every coil spring that is accessible to the occupant of a crib, cradle or bassinet must be covered or constructed so as to prevent injury.

Marginal note:Opening or slot

25 Every opening or slot in a wooden, plastic or metal part of a crib, cradle or bassinet — or in a part of one of a similar hard material — that is accessible to its occupant must

(a) be of such a size and shape that, if it admits a rod 5.33 mm in diameter, it will also admit a rod 9.53 mm in diameter; or

(b) have a depth that is not greater than the minor span dimension, if the minor span dimension across the opening or slot is greater than or equal to 5.33 mm and less than 9.53 mm.

Cribs

Marginal note:Height of stationary sides — mattress support in lowest position

26 (1) The upper surface of the mattress support of a crib, when the mattress support is in its lowest position, must be

(a) at least 660 mm lower than the upper surface of the lowest stationary side; and

(b) not lower than the lower surface of any stationary side.

Marginal note:Height of movable sides — mattress support in lowest position

(2) Every movable side of a crib must have an adjustment position in which the upper surface of the mattress support, when the mattress support is in its lowest position, is

(a) at least 660 mm lower than the upper surface of the movable side; and

(b) not lower than the lower surface of any movable side.

Marginal note:Height of sides — mattress support in highest position

27 The upper surface of the mattress support of a crib, when the mattress support is in its highest position, must be

(a) at least 230 mm lower than the upper surface of the lowest stationary side; and

(b) if the crib has a movable side and when that side is in any adjustment position, at least 230 mm lower than the upper surface of either

(i) the movable side, or

(ii) the stationary part of the movable side, if only part of the side is movable.

Marginal note:Height of move-upward sides

28 The lower surface of the movable part of each move-upward side of a crib must, in every adjustment position in which that surface is moved upward, be at least 360 mm higher than the upper surface of the stationary part of the side.

Marginal note:Latching or locking mechanism — movable sides

29 (1) Every movable side of a crib must be held in each of its adjustment positions by means of a mechanism that both

(a) latches or locks automatically; and

(b) requires two separate, deliberate and simultaneous actions on the part of the user to unlatch or unlock it.

Marginal note:Latching or locking mechanism — move-upward sides in highest position

(2) In addition to the requirement of paragraph (1)(b), every move-upward side of a crib must, in its highest adjustment position, have a mechanism that requires a push or pull force of at least 35 N or a torque of at least 8 N•m to unlatch or unlock it.

Marginal note:Latching or locking mechanism — move-upward sides

(3) Every move-upward side of a crib must, in every adjustment position in which the lower surface of the movable part of the side is at least 360 mm above the upper surface of the stationary part of the side, remain in that adjustment position when a pull force of 200 N is applied to the side along its plane, at any point along the length of the bottom rail of the side, in a direction perpendicular to the side.

Marginal note:Latching or locking mechanism — rotating sides

(4) The latching or locking mechanism of every rotating side of a crib must remain latched or locked when a force of 200 N is applied towards the exterior of the crib at any point either

(a) on that side or on any part of the mechanism, if the whole side rotates; or

(b) on the rotating part of that side or on any part of the mechanism, if only part of the side rotates.

Marginal note:Latching or locking mechanism — move-sideways sides

(5) The latching or locking mechanism of every move-sideways side of a crib must remain latched or locked when a force of 200 N is applied in any direction to any point on that side or on any part of the mechanism.

Marginal note:Latching or locking mechanism — folding cribs

30 Every crib that folds must have a latching or locking mechanism that engages automatically, that requires two separate, deliberate and simultaneous actions on the part of the user to unlatch or unlock it, and that prevents the crib from folding or collapsing when tested in accordance with Schedule 7.

Marginal note:Posts

31 (1) Subject to subsection (2), a crib must not have any post that extends more than 3 mm above the lowest point, within a radius of 76 mm from the centre line of the post, on the upper surface of the higher adjoining side of the crib.

Marginal note:Exception

(2) A post of a crib may extend more than 406 mm above the highest point on the upper surface of the higher adjoining side if the crib meets the requirements set out in section 1508.11 of part 1508, chapter II, title 16 of the Code of Federal Regulations of the United States, as it read on January 1, 2004.

Marginal note:Extensions

(3) A post of a crib whose height may be extended by the attachment of a removable extension must meet the requirements of subsection (2) if any one or more of the segments of that extension are attached to the crib.

Marginal note:Toeholds

32 (1) A crib must be constructed so that the upper surface of any bar, rail, rod, projection or ledge that is capable of being used as a toehold by the occupant of the crib is not located at any point from 150 mm to 510 mm above the upper surface of the mattress support, when the mattress support is in its lowest position and each movable side is in an adjustment position described in subsection 26(2).

Marginal note:Presumption

(2) For the purpose of subsection (1), a bar, rail, rod, projection or ledge is capable of being used as a toehold if it has a depth of 10 mm or more.

Marginal note:Mattress support

33 When tested in accordance with Schedule 8, the mattress support of a crib must not dislodge, its mechanisms must not disengage or deform permanently and its fasteners must not loosen.

Marginal note:Structural integrity

34 When tested in accordance with Schedule 7, a crib must not exhibit any damage, its latching or locking mechanisms must not disengage or deform permanently and its mattress support fasteners must not loosen.

Cradles

Marginal note:Height of sides — general

35 (1) The lower surface of each side of a cradle must not be higher than the upper surface of the mattress support.

Marginal note:Height of sides — mattress support in any position

(2) The upper surface of the mattress support of a cradle, when the mattress support is in any position, must be

(a) at least 230 mm lower than the upper surface of the lowest stationary side; and

(b) if the cradle has a movable side and when that side is in any adjustment position, at least 230 mm lower than the upper surface of either

(i) the movable side, or

(ii) the stationary part of the movable side, if only part of the side is movable.

Marginal note:Height of move-upward sides

36 The lower surface of the movable part of each move-upward side of a cradle must, in every adjustment position in which that surface is moved upward, be at least 360 mm higher than the upper surface of the stationary part of the side.

Marginal note:Latching or locking mechanism — movable sides

37 (1) Every movable side of a cradle must be held in each of its adjustment positions by means of a mechanism that both

(a) latches or locks automatically; and

(b) requires two separate, deliberate and simultaneous actions on the part of the user to unlatch or unlock it.

Marginal note:Latching or locking mechanism — move-upward sides in highest position

(2) In addition to the requirement of paragraph (1)(b), every move-upward side of a cradle must, in its highest adjustment position, have a mechanism that requires a push or pull force of at least 35 N or a torque of at least 8 N•m to unlatch or unlock it.

Marginal note:Latching or locking mechanism — move-upward sides

(3) Every move-upward side of a cradle must, in every adjustment position in which the lower surface of the movable part of the side is at least 360 mm above the upper surface of the stationary part of the side, remain in that adjustment position when a pull force of 200 N is applied to the side along its plane, at any point along the length of the bottom rail of the side, in a direction perpendicular to the side.

Marginal note:Latching or locking mechanism — rotating sides

(4) The latching or locking mechanism of every rotating side of a cradle must remain latched or locked when a force of 200 N is applied toward the exterior of the cradle at any point either

(a) on that side or on any part of the mechanism, if the whole side rotates; or

(b) on the rotating part of that side or on any part of the mechanism, if only part of the side rotates.

Marginal note:Latching or locking mechanism — move-sideways sides

(5) The latching or locking mechanism of every move-sideways side of a cradle must remain latched or locked when a force of 200 N is applied in any direction to any point on that side or on any part of the mechanism.

Marginal note:Latching or locking mechanism — folding cradles

38 Every cradle that folds must have a latching or locking mechanism that engages automatically, that requires two separate, deliberate and simultaneous actions on the part of the user to unlatch or unlock it, and that prevents the cradle from folding or collapsing when tested in accordance with Schedule 7.

Marginal note:Mattress support

39 When tested in accordance with Schedule 8, the mattress support of a cradle must not dislodge, its mechanisms must not disengage or deform permanently and its fasteners must not loosen.

Marginal note:Structural integrity

40 When tested in accordance with Schedule 7, a cradle must not exhibit any damage, its latching or locking mechanisms must not disengage or deform permanently and its mattress support fasteners must not loosen.

Bassinets

Marginal note:Height of sides — general

41 (1) The lower surface of each side of a bassinet must not be higher than the upper surface of the mattress support.

Marginal note:Height of sides

(2) The upper surface of the mattress support of a bassinet, when the mattress support is in any position, must be at least 230 mm lower than the upper surface of the lowest stationary side.

Marginal note:Structural solidity

42 Every part of the mattress support of a bassinet must be capable of supporting a load of 24 kg uniformly distributed over an area of 2.3 × 104 mm2 for a period of one minute without any damage to any component of the bassinet.

Documents

Marginal note:Period of retention

43 (1) The person responsible must keep documents that show that a crib, cradle or bassinet meets the requirements of these Regulations, for a period of at least three years after the date of its manufacture in Canada or the date of its importation.

Marginal note:Inspection

(2) The person responsible must provide an inspector with any documents that the inspector requests in writing, within 15 days after receipt of the request.

Repeal

44 [Repeal]

Coming into Force

Marginal note:Registration

45 These Regulations come into force on the day on which they are registered.

SCHEDULE 1(Paragraph 6(1)(b))Standard Sans-Serif Type

FIGURE 1

SCHEDULE 2(Section 16)Test for Strength and Solidity of Slats

1 The method to be used for testing the strength and solidity of crib, cradle and bassinet slats is as follows:

(a) assemble the crib, cradle or bassinet according to the manufacturer’s instructions, omitting accessories that could interfere with the conduct of the test;

(b) secure the crib, cradle or bassinet to a horizontal surface in the manufacturer’s recommended use position in a manner that will not interfere with the conduct of the test;

(c) apply a torque of 8 N•m to one of the slats at its midpoint and maintain the torque for 10 seconds;

(d) record any turning, dislodging or deformation of the slat and any damage to the slat;

(e) repeat the procedures set out in paragraphs (c) and (d) for every other slat;

(f) apply a vertical upward force of 500 N at the midpoint of the top rail on one of the sides to which slats are attached and maintain the force for 30 seconds;

(g) record any dislodging of any of the slats from the top or bottom rail and any damage to the slats; and

(h) repeat the procedures set out in paragraphs (f) and (g) for every other side to which slats are attached.

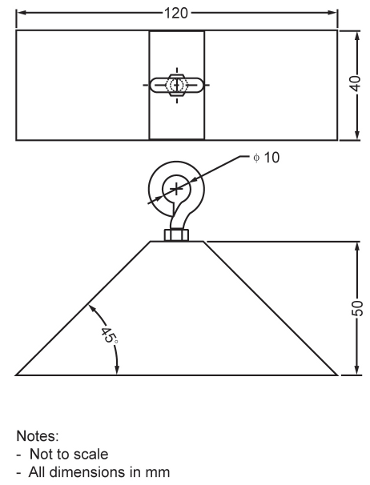

SCHEDULE 3(Section 17)Test for Openings

Cribs

1 The method to be used for testing completely bounded openings that are located above the mattress support of a crib when the mattress support is in its lowest position is as follows:

(a) assemble the crib according to the manufacturer’s instructions, omitting accessories that could interfere with the conduct of the test;

(b) if the mattress support is adjustable, adjust it to its lowest position;

(c) place a metallic loading wedge of the dimensions illustrated in Figure 1 in the opening between two adjacent slats, midway along the greatest dimension of the opening;

(d) apply a pull force of 90 N to the eyebolt of the loading wedge in a direction perpendicular to a plane passing through the points of contact of the wedge with the two slats, and maintain the force for 10 seconds;

(e) while applying the pull force of 90 N in accordance with paragraph (d), attempt to pass, without forcing, a solid rectangular block with dimensions of 60 mm × 100 mm × 100 mm through the opening, anywhere above or below the loading wedge;

(f) repeat the procedure set out in paragraph (e) with the block in all other possible orientations;

(g) repeat the procedures set out in paragraphs (c) to (f) for all other openings between adjacent slats; and

(h) attempt to pass, without forcing, a solid rectangular block with dimensions of 60 mm × 100 mm × 100 mm through every opening in every part of the crib that is located above the mattress support.

Cradles and Bassinets

2 The method to be used for testing completely bounded openings that are located above the mattress support of a cradle or bassinet is as follows:

(a) assemble the cradle or bassinet according to the manufacturer’s instructions, omitting accessories that could interfere with the conduct of the test;

(b) attempt to pass, without forcing, a solid rectangular block with dimensions of 60 mm × 100 mm × 100 mm through the opening between any adjacent slats;

(c) repeat the procedure set out in paragraph (b) with the block in all other possible orientations;

(d) repeat the procedures set out in paragraphs (b) and (c) for all other openings between adjacent slats; and

(e) attempt to pass, without forcing, a solid rectangular block with dimensions of 60 mm × 100 mm × 100 mm through every opening in every part of the cradle or bassinet that is located above the mattress support.

FIGURE 1

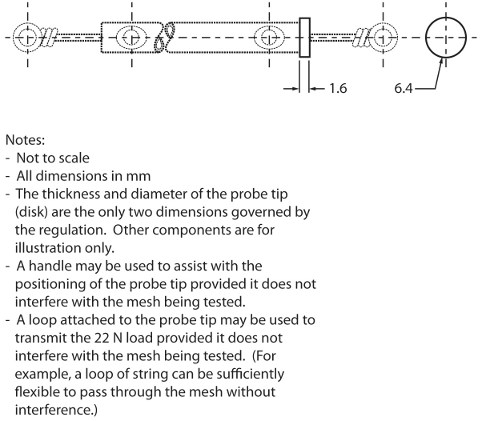

SCHEDULE 4(Subsection 19(1))Test for Determination of Mesh Opening Sizes

1 The method to be used for testing the size of mesh openings on a crib, cradle or bassinet is as follows:

(a) cut a sample of mesh with dimensions of 305 mm × 305 mm;

(b) apply a uniformly distributed test load of 0.15 N/mm to two opposite edges of the sample so as to induce a state of uniaxial tension in the sample;

(c) attempt to insert the tip of the probe illustrated in Figure 1 through openings in the mesh, without cutting the fibres of the mesh, using a force of not more than 22 N at 10 randomly selected areas in the sample; and

(d) repeat the procedures set out in paragraphs (b) and (c) on the other two opposite edges of the sample.

FIGURE 1

SCHEDULE 5(Subsection 19(2))Test for Strength of Mesh and Integrity of Attachment

1 The method to be used for testing the strength of mesh and the integrity of attachment of mesh to a crib, cradle or bassinet is as follows:

(a) assemble the crib, cradle or bassinet according to the manufacturer’s instructions, omitting accessories that could interfere with the conduct of the test;

(b) secure the crib, cradle or bassinet to a horizontal surface on its side, in a manner that will not interfere with the conduct of the test, so that a side with a panel of mesh is positioned above its opposite side;

(c) use any blocking or support necessary to maintain the position described in paragraph (b) if the blocking does not act directly on the frame of the side being tested;

(d) apply a metal loading block, having a mass of 9.18 kg and a base with dimensions of 150 mm × 75 mm, at the geometric centre of the panel of mesh or, if exterior framing interferes with the test, as close as possible to the geometric centre, with the 150 mm sides running transversely to the outermost edge of the side being tested, in the following manner:

(i) gradually apply the loading block over a period of 5 seconds,

(ii) allow the loading block to act for 10 seconds,

(iii) gradually remove the loading block over a period of 5 seconds, and

(iv) allow a 10-second recovery time;

(e) repeat the procedures set out in paragraph (d) 10 times;

(f) repeat the procedures set out in paragraphs (d) and (e) on the following areas of the mesh:

(i) on the top portion of the panel of mesh, with the closer 75-mm edge of the loading block applied at a distance ranging from 25 mm to 50 mm from the centre of the top portion of the mesh at the transverse centre line of the panel, and

(ii) on the bottom portion of the panel of mesh, with the closer 75-mm edge of the loading block applied at a distance ranging from 25 mm to 50 mm from the centre of the bottom portion of the mesh at the transverse centre line of the panel; and

(g) repeat the procedures set out in paragraphs (b) to (f) on every other panel of mesh on the crib, cradle or bassinet, if applicable.

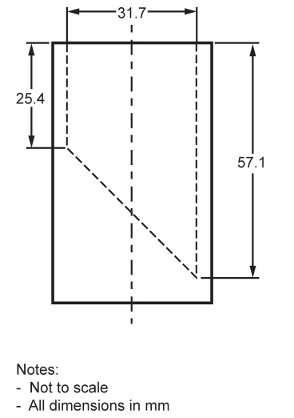

SCHEDULE 6(Section 23)Small Parts Cylinder

FIGURE 1

SCHEDULE 7(Sections 30, 34, 38 and 40)Test for Structural Integrity

Cribs

1 The method to be used for testing the structural integrity of a crib under dynamic conditions is as follows:

(a) assemble the crib according to the manufacturer’s instructions, omitting accessories that could interfere with the conduct of the test;

(b) secure the crib to a horizontal surface in the manufacturer’s recommended use position in a manner that will not interfere with the conduct of the test;

(c) place on the mattress support a 100-mm thick sheet of polyurethane foam that has a density of 30 kg/m3, a 25% indentation force deflection of 144 N and a length and width that meet the requirements of paragraph 20(b) of these Regulations;

(d) using a 20-kg test load of the dimensions illustrated in Figure 1, allow the test load to fall freely, from a height of 150 mm above the initial position of the upper surface of the sheet of polyurethane foam, 150 times at a rate of one impact per second at the geometric centre of the surface of the sheet, in such a manner that the upper surface of the test load remains parallel to the horizontal surface referred to in paragraph (b);

(e) record any damage to the crib, any disengagement or permanent deformation of its latching or locking mechanisms and any loosening of its mattress support fasteners;

(f) without readjusting the mattress support, repeat the procedures set out in paragraphs (d) and (e), except that, at each of the mattress support mechanisms, allow the test load to fall at a point that, when measured from the geometric centre of the test load, is 150 mm from the innermost surfaces of the sides nearest the mattress support being tested, measured at the level of the upper surface of the sheet of polyurethane foam; and

(g) repeat the procedures set out in paragraphs (d) and (e), except that, at the midpoint along the edge of the mattress support beside each movable side, allow the test load to fall at a point that, when measured from the geometric centre of the test load, is 150 mm from that side measured at the level of the upper surface of the sheet of polyurethane foam.

2 The method to be used for testing the structural integrity of a crib under horizontal force conditions is as follows:

(a) assemble the crib according to the manufacturer’s instructions, omitting accessories that could interfere with the conduct of the test;

(b) secure the crib to a horizontal surface in the manufacturer’s recommended use position in a manner that will not interfere with the conduct of the test;

(c) with any movable sides of the crib in the adjustment position designed to provide accommodation for an unattended child and using a point that is midway along the length of one of the sides, but not more than 50 mm from the upper edge of the side, as the point of contact, apply a horizontal force of 120 N perpendicularly to the side in a back-and-forth motion at a frequency of 150 cycles per minute for a total of 9 000 cycles;

(d) record any damage to the crib, any disengagement or permanent deformation of its latching or locking mechanisms and any loosening of its mattress support fasteners; and

(e) repeat the procedures set out in paragraphs (c) and (d) for every other side of the crib.

3 The method to be used for testing the structural integrity of a crib under vertical force conditions is as follows:

(a) assemble the crib according to the manufacturer’s instructions, omitting accessories that could interfere with the conduct of the test;

(b) secure the crib to a horizontal surface in the manufacturer’s recommended use position in a manner that will not interfere with the conduct of the test;

(c) with any movable sides of the crib in the adjustment position designed to provide accommodation for an unattended child and using the midpoint of the top of one of the sides as the point of contact, apply a vertical force of 120 N in an up-and-down motion at a frequency of 150 cycles per minute for a total of 9 000 cycles;

(d) record any damage to the crib, any disengagement or permanent deformation of its latching or locking mechanisms and any loosening of its mattress support fasteners; and

(e) repeat the procedures set out in paragraphs (c) and (d) for every other side of the crib.

Cradles

4 The method to be used for testing the structural integrity of a cradle under dynamic conditions is as follows:

(a) assemble the cradle according to the manufacturer’s instructions, omitting accessories that could interfere with the conduct of the test;

(b) secure the cradle to a horizontal surface in the manufacturer’s recommended use position in a manner that will prevent it from rocking or swinging;

(c) place on the mattress support a 80-mm thick sheet of polyurethane foam that has a density of 30 kg/m3, a 25% indentation force deflection of 144 N and a length and width that meet the requirements of paragraph 20(b) of these Regulations;

(d) using a 13.7-kg test load that has a square contact area of 929 cm2, allow the test load to fall freely, from a height of 150 mm above the initial position of the upper surface of the sheet of polyurethane foam, 500 times at a rate of one impact per second at the geometric centre of the surface of the sheet; and

(e) record any damage to the cradle, any disengagement or permanent deformation of its latching or locking mechanisms and any loosening of its mattress support fasteners.

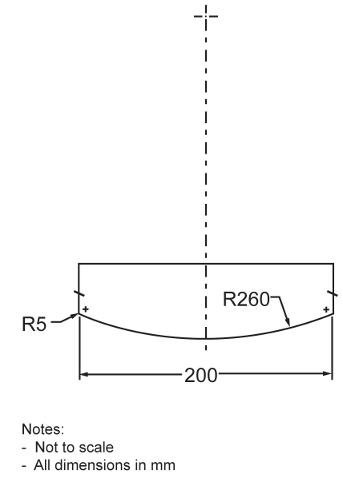

FIGURE 1

SCHEDULE 8(Sections 33 and 39)Test of Mattress Support

Cribs

1 The method to be used for testing the mattress support of a crib is as follows:

(a) assemble the crib according to the manufacturer’s instructions, omitting accessories that could interfere with the conduct of the test;

(b) secure the crib to a horizontal surface in the manufacturer’s recommended use position in a manner that will not interfere with the conduct of the test;

(c) apply and maintain for one minute an upward push force of 250 N as close as possible to and within a radius of 150 mm from the lower surface of one of the crib’s mattress support mechanisms;

(d) record any dislodging of the mattress support, any disengagement or permanent deformation of the mattress support mechanisms and any loosening of the fasteners;

(e) readjust the mattress support to its original position, if necessary;

(f) repeat the procedures set out in paragraphs (c) to (e) for every other mattress support mechanism;

(g) apply simultaneously and maintain for one minute an upward push force of 250 N as close as possible to and within a radius of 150 mm from the lower surface of each of the mattress support mechanisms;

(h) record any dislodging of the mattress support, any disengagement or permanent deformation of the mattress support mechanisms and any loosening of the fasteners;

(i) readjust the mattress support to its original position, if necessary;

(j) apply a force of 200 N in any direction to one of the mattress support mechanisms in a manner that could cause disengagement or permanent deformation of the mechanism or loosening of the mattress support fasteners;

(k) record any dislodging of the mattress support, any disengagement or permanent deformation of the mattress support mechanisms and any loosening of the fasteners;

(l) readjust the mattress support to its original position, if necessary; and

(m) repeat the procedures set out in paragraphs (j) to (l) for every other mattress support mechanism.

Cradles

2 The method to be used for testing the mattress support mechanism of a cradle is as follows:

(a) assemble the cradle according to the manufacturer’s instructions, omitting accessories that could interfere with the conduct of the test;

(b) secure the cradle to a horizontal surface in the manufacturer’s recommended use position in a manner that will prevent it from rocking or swinging;

(c) apply and maintain for one minute an upward push force of 250 N as close as possible to and within a radius of 150 mm from the lower surface of one of the mattress support mechanisms;

(d) record any dislodging of the mattress support, any disengagement or permanent deformation of the mattress support mechanisms and any loosening of the fasteners;

(e) readjust the mattress support to its original position, if necessary;

(f) repeat the procedures set out in paragraphs (c) to (e) for every other mattress support mechanism;

(g) apply simultaneously and maintain for one minute an upward push force of 250 N as close as possible to and within a radius of 150 mm radius from the lower surface of the mattress support mechanisms; and

(h) record any dislodging of the mattress support, any disengagement or permanent deformation of the mattress support mechanisms and any loosening of the fasteners.

- Date modified: