Small Fishing Vessel Inspection Regulations

C.R.C., c. 1486

Regulations Respecting the Construction and Inspection of Fishing Vessels not Exceeding 24.4 m in Length that do not Exceed 150 Tons, Gross Tonnage

Short Title

1 These Regulations may be cited as the Small Fishing Vessel Inspection Regulations.

Interpretation

2 In these Regulations,

- Act

Act means the Canada Shipping Act; (Loi)

- amidships

amidships means the mid-point of the length of a fishing vessel; (milieu du bateau)

- Board

Board means the Board of Steamship Inspection; (Bureau)

- Chairman

Chairman means the Chairman of the Board; (président)

- Class II EPIRB

Class II EPIRB means an emergency position indicating radiobeacon; (RLS de classe II)

- closed construction

closed construction, with respect to a fishing vessel, means a fishing vessel of which more than 50 per cent of the length is covered full width, at or above the gunwale level, by decks or permanent enclosures; (bateau ponté)

- Divisional Supervisor

Divisional Supervisor means the officer of the Department of Transport in charge of a Steamship Inspection Division and includes the Regional Superintendent of a Steamship Inspection Division; (surveillant divisionnaire)

- existing

existing, when used with reference to a fishing vessel, means a fishing vessel that is not new; (existant)

- fishing vessel

fishing vessel means a vessel that is to be used in commercial fishing or that is engaged in commercial fishing and includes a rockweed harvester vessel; (bateau de pêche)

- inspector

inspector means a steamship inspector appointed under the Act; (inspecteur)

- length

length means,

(a) in the case of a vessel that is registered under the Act or required by the Act to be registered,

(i) the distance from the fore part of the uppermost end of the stem to the aft side of the head of the stern post except that if a stern post is not fitted to the vessel the measurement shall be taken to the foreside of the head of the rudder stock, or

(ii) if the vessel has no rudder stock or has a rudder stock situated outside of the hull at the stern, the distance from the foreside of the foremost permanent structure to the aft side of the aftermost permanent structure of the vessel, not including guards or rubbing strakes, and

(b) in the case of a vessel other than a vessel described in paragraph (a), the horizontal distance measured between perpendiculars erected at the extreme ends of the outside of the hull; (longueur)

- new

new, when used with reference to a fishing vessel or article, means that the construction of the fishing vessel or article was commenced on or after January 6, 1965, and includes any foreign fishing vessel brought under Canadian registry whether or not its construction was commenced before or after that date; (neuf)

- open construction

open construction, with respect to a fishing vessel, means a fishing vessel other than one of closed construction; (bateau non ponté)

- sailing ship

sailing ship means

(a) a ship propelled wholly by sails, and

(b) a ship principally employed in fishing not exceeding 200 tons, gross tonnage, provided with masts, sails and rigging sufficient to allow it to make voyages under sail alone, and that, in addition, is fitted with a mechanical means of propulsion other than a steam engine; (voilier ou navire à voiles)

- SART

SART means a radar transponder designed for search and rescue purposes; (répondeur SAR)

- subsidized vessel

subsidized vessel[Repealed, SOR/79-905, s. 1]

- survival craft

survival craft means a vessel carried pursuant to section 30 as life saving equipment on board a fishing vessel; (bateau de sauvetage)

- TP 127

TP 127 means the Ship Safety Electrical Standards, issued by the Department of Transport, as amended from time to time. (TP 127)

- SOR/79-905, s. 1

- SOR/96-217, s. 1

- SOR/99-215, s. 4

- SOR/2000-262, s. 1

General

3 Every life raft, rocket, flare or signal required by these Regulations for a fishing vessel shall be of a type approved by the Board and constructed in accordance with the standards for such equipment prescribed in the Life Saving Equipment Regulations.

- SOR/96-217, s. 6

4 [Repealed, SOR/99-215, s. 5]

PART IFishing Vessels Exceeding 15 Tons, Gross Tonnage

Application

5 (1) Subject to subsections (2) and (3), this Part applies to every fishing vessel that

(a) exceed 15 tons, gross tonnage, but does not exceed 150 tons, gross tonnage;

(b) does not exceed 24.4 m in length; and

(c) is not a sailing ship.

(2) Sections 6, 7, 9, 11 to 28, 43 and 44 apply only to a new fishing vessel.

(3) Section 29 applies only to a fishing vessel of closed construction employed in catching herring or capelin where, on or after July 6, 1977,

(a) its keel was laid;

(b) it was registered as a Canadian ship;

(c) it was converted to herring or capelin fishing; or

(d) it underwent such modification that its stability characteristics were adversely affected.

- SOR/78-429, ss. 1, 2

- SOR/82-129, s. 2

- SOR/85-43, s. 1(E)

- SOR/95-372, s. 7

Submission and Approval of Plans, etc.

6 (1) Subject to section 7, before commencement of construction of a fishing vessel, the builder or owner of the fishing vessel shall submit in triplicate to the Ship Safety Branch office for the area in which the fishing vessel will be constructed, the scantlings, information and data set out in Schedule I concerning the propelling machinery, boilers and air receivers, bilge pumps and piping, fire pumps and piping, fuel systems including ventilating arrangements, steering gear, hull and electrical system of the fishing vessel.

(2) Notwithstanding subsection (1), the data set out in paragraph (h) of Schedule I is required to be submitted only in respect of fishing vessels to which section 29 applies.

(3) Before commencement of construction of a fishing vessel, the owner of the fishing vessel shall submit to the Ship Safety Branch office for the area in which it is proposed to construct the fishing vessel detailed plans and data of any of the following equipment with which the fishing vessel is to be equipped, namely, its main, auxiliary and heating boilers (other than heating boilers having a working pressure not exceeding 103 kPa), steam pipes, boiler mountings and air receivers.

- SOR/79-905, s. 2

- SOR/82-299, s. 1

- SOR/89-283, s. 1

7 (1) Where, under subsection 6(1) or (2), any scantling, information, data or plans are submitted to a Ship Safety Branch office, an inspector shall approve them if, in the inspector’s opinion,

(a) the scantlings, information, data or plans conform with the requirements of sections 9 to 29 where those sections are applicable; and

(b) the vessel, if constructed in accordance with those scantlings, information, data or plans, will be safe and suitable for the voyages for which it is intended.

(2) Where, under subsection 6(3), plans and data are submitted to a Ship Safety Branch office respecting any equipment mentioned in that subsection, that office shall send them to the Chairman who shall approve the plans if the equipment conforms with the requirements of the Marine Machinery Regulations.

- SOR/82-129, s. 3

- SOR/89-283, s. 2

- SOR/95-372, s. 7

8 No inspection certificate shall be issued in respect of a fishing vessel unless

(a) the scantlings, information, data and plans required to be submitted under section 6 have been submitted under that section and have been approved under section 7;

(b) the vessel is constructed in accordance with

(i) the scantlings, information, data and plans referred to in paragraph (a), and

(ii) the requirements of these Regulations; and

(c) the requirements of section 29 have been met, where applicable, in respect of the vessel.

- 1987, c. 7, s. 84(F)

Bilge Pumping Arrangements

9 (1) Every fishing vessel not exceeding 15.2 m in length shall be provided with one bilge power or hand pump having a capacity of not less than 1.14 L/s.

(2) Every fishing vessel exceeding 15.2 m and not exceeding 19.8 m in length shall be provided with two bilge pumps, each having a capacity of not less than 1.14 L/s, one of which shall be a power pump and the other either a power pump or a hand pump, but where two power pumps are provided, they are not to be driven by the same engine.

(3) Subject to subsection (4), every fishing vessel exceeding 19.8 m and not exceeding 24.4 m in length shall be provided with at least two bilge pumps, each having a capacity of not less than 2.28 L/s, one of which shall be a power pump and the other either a power pump or a hand pump, but where two power pumps are provided, they are not to be driven by the same engine.

(4) Two or more pumps, each with a capacity of not less than 1.14 L/s, may, if they can be used simultaneously, be provided on a fishing vessel in lieu of one only of the pumps required by subsection (3); if the pumps provided under this subsection are power pumps, they may be driven from the one engine, but not from the engine that is used to drive the mandatory power pump.

(5) Subject to subsection (6), bilge piping arrangements on a fishing vessel shall be such that each of the bilge pumps required by subsection (1), (2), (3) or (4) can draw water from each of the bilge suctions required by subsection (7) or (8).

(6) Bilge piping and pumping arrangements that provide a piping and pumping system at least as efficient as those described in subsection (5) may be provided on a fishing vessel.

(7) Bilge suctions and means for drainage on a fishing vessel that is divided into watertight compartments shall be so arranged that any water that enters any main watertight compartment can be pumped out, through at least one bilge suction situated in that compartment, and all compartments within each main division shall be arranged to drain to that bilge suction.

(8) Bilge suctions and means for drainage on a fishing vessel that is not divided into watertight compartments shall be so arranged that any water that enters the vessel is able to drain to at least one bilge suction.

(9) Bilge piping on a fishing vessel shall have an internal diameter of not less than 38 mm except in the case of bilge piping on a fishing vessel not exceeding 15.2 m in length in which fish sludge, scale or offal is not usually pumped, in which case the bilge piping shall have an internal diameter of not less than 25 mm.

(10) Hand bilge pumps on a fishing vessel shall be capable of being worked from a position above the load water line.

(11) Each bilge branch suction line on a fishing vessel, except hand pumps with only one suction, shall be fitted with a stop valve that is readily accessible at all times.

(12) Where a bilge pump on a fishing vessel is fitted with a connection to the sea, a non-return valve or swing check valve that is readily accessible shall be fitted between the sea connection and the bilge main so that sea water cannot flow into the bilges when sea connection and bilge valves are open.

(13) Bilge suctions that lead into crew spaces or engine rooms of a fishing vessel shall be fitted with strainers and the area of the openings of such strainers shall not be less than twice the cross-sectional area of the bilge pipe.

(14) Subject to subsection (15), the piping for bilge pumps on a fishing vessel shall be of steel, bronze or other material that, in the opinion of the Board, is suitable for the purpose, and the joints for such piping shall be flanged or screwed.

(15) Where it is necessary to reduce the effect of vibration, short lengths of rubber or plastic hose may be installed and shall

(a) be clearly visible at all times;

(b) be of sufficient strength to withstand collapsing due to suction; and

(c) have joints made with clamps suitable for the purpose.

- SOR/95-372, s. 7

Fuel Systems Including Ventilating Arrangements

10 (1) A fuel tank on a fishing vessel that is separate from the hull shall comply with the following rules:

(a) it shall be made of steel or other suitable material the strength of which is equivalent to that of steel;

(b) where a fuel tank is made of material other than steel and the vessel is a steel vessel, the fuel tank shall be efficiently isolated from the steel structure of the vessel;

(c) where a fuel tank is made of steel, the steel plating shall have a minimum thickness calculated in accordance with the following table:

TABLE

Capacity of tank in litres Minimum thickness of steel plating in millimetres More than 114 and not more than 1 364

3 More than 1 364 and not more than 4 550

5 More than 4 550

6 (c.1) where a fuel tank is made of material other than steel, the material used for plating shall be of such thickness as to provide a strength equal to or greater than the strength of the steel plating required in accordance with paragraph (c);

(c.2) subject to paragraph (c.3), where the capacity of a fuel tank is more than 114 L, the tank is made of steel and the thickness of the plating is the thickness set out in Column I of an item of the table to this paragraph, the tank shall be fitted with stiffeners so that the unsupported flat surfaces of the tank do not exceed, in square metres, the area set out in Column II of that item:

TABLE

Column 1 Column 2 Item Thickness of steel plating in millimetres Unsupported flat surface area in square metres 1 3 0.28 2 5 0.56 3 6 0.84 (c.3) where the thickness of the tank plating is intermediate to any set out in the table to paragraph (c.2), the unsupported flat surface area shall be calculated by interpolation and, where such thickness exceeds 6 mm, the unsupported flat surface shall be calculated in accordance with that table by extrapolation;

(c.4) subject to paragraphs (c.5) and (c.6), where the capacity of a fuel tank is more than 114 L, the tank is made of material other than steel and the thickness of the tank’s plating is such as to provide a strength equal to or greater than the strength of steel plating having a thickness set out in Column I of an item of the table to paragraph (c.2), the tank shall be fitted with stiffeners so that the unsupported flat surfaces of the tank do not exceed, in square metres, the area set out in Column II of that item;

(c.5) where the thickness of the tank plating made of material other than steel is such as to provide a strength equal to the strength of steel plating referred to in the table to paragraph (c.2) and is intermediate to any set out in that table, the unsupported flat surface area shall be calculated by interpolation;

(c.6) where the thickness of the tank plating made of material other than steel is such as to provide a strength that exceeds the strength of 6 mm of steel, the unsupported flat surface area shall be calculated in accordance with the table to paragraph (c.2) by extrapolation;

(d) where the length or breadth of a fuel tank is greater than 1.22 m, baffle plates shall be fitted inside the tank in sufficient numbers that the distance between baffle plates or between a baffle plate and a side plate is not greater than 1.22 m;

(e) a fuel tank having a capacity exceeding 1 364 L and not exceeding 4 550 L shall be fitted with a suitable clean-out door, and a fuel tank having a capacity of more than 4 550 L shall be fitted with a manhole door;

(f) where the capacity does not exceed 114 L it may be constructed of material that is less than 3 mm in thickness, but when such tank is to be used for gasoline and has a capacity exceeding 23 L and is made of material of less than 3 mm in thickness that is not corrosion resistant, it shall be galvanized inside and outside by the hot-dipped process after construction is completed;

(g) mass produced cylindrical gasoline drums having a capacity exceeding 23 L and not exceeding 227 L may be used as fuel tanks without alteration if they

(i) have been galvanized inside and out and are constructed of steel plate having a thickness of not less than 1.5 mm, corrugated to give extra strength, and

(ii) do not weigh less than 32 kg when empty if they have a capacity of approximately 205 L;

(h) a fuel tank having a capacity exceeding 114 L shall be tested hydrostatically on completion to a head of at least 2.44 m above the crown or to the maximum head to which the tank will be subjected, whichever is the greater, such tests shall be witnessed by an inspector, but in the case of any tank of a capacity not exceeding 1 364 L the inspector may, when it is not practicable for him to witness the test, accept a written statement from the manufacturer certifying that the hydrostatic test described in this paragraph has been carried out and that no defects were revealed; and

(i) seams shall be welded, brazed or double riveted, but soldered joints may be used on a tank having a capacity of not over 114 L if the solder has a melting point of not less than 427°C.

(2) A fuel tank that is not separate from the hull of a fishing vessel shall be considered as part of the hull, taking into consideration the strength requirements of the vessel and the possibility of contamination of oil fuel with water, but the standards of construction and testing shall not be less than those set out in this section for a fuel tank that is separate from the hull.

(3) Where the capacity of a fuel tank exceeds 114 L, it shall be provided with the following:

(a) a filling pipe that

(i) is at least 38 mm inch in internal diameter,

(ii) leads from the top of the tank to the weatherdeck, the connection through the deck being watertight,

(iii) is fitted with a screwed brass plug or cap, and

(iv) is made sufficiently flexible to absorb any vibration or sinkage of the tank; and

(b) a vent or breather pipe that

(i) leads from the top of the tank to a safe height and location above the weather deck and is clear of all openings into the hull or deck house,

(ii) has the end covered with wire gauze and turned down through an angle of 180 degrees,

(iii) has a weathertight deck connection,

(iv) may have two or more vent pipes branching off from the pipe leading to the deck if that pipe is increased in diameter to maintain the required cross sectional area, and

(v) shall, for each tank, be,

(A) where the only exit for overflow is the vent pipe, not less in internal diameter than the filling pipe, and

(B) where the overflow can take place from the filling pipe and the arrangements are such that supply nozzles cannot plug the filling pipe, not less in internal diameter than one-fifth of the internal diameter of the filling pipe.

(4) Glass tubing shall not be used on a fishing vessel as a gauge glass on a fuel tank having a capacity of more than 114 L or on any fuel tank that contains fuel having a flashpoint of less than 52°C (Pensky-Marten closed cup), but flat glass gauges of a type approved by the Board may be used on any fuel tank if fitted with self-closing cocks or valves.

(5) Where glass tubing is used as a gauge on a fuel tank on a fishing vessel, the gauge shall be fitted with a cock or valve at the top and at the bottom.

(6) Where a drain valve or cock is provided on a fuel tank on a fishing vessel, it shall have a standard screwed outlet that shall be kept plugged with a screwed plug whenever the cock or valve is not in use.

(7) The piping from any fuel tank on a fishing vessel shall be fitted at the tank with a valve or cock that is capable of being operated from outside the compartment in which the tank is situated.

(8) Where a new or existing fishing vessel is equipped with an oil-fired power boiler for main or auxiliary steam, each valve or cock fitted to a fuel tank shall be so controlled that it is capable of being shut off from a position that is

(a) outside the compartment in which the fuel tank is situated; and

(b) always accessible in the event of fire taking place in the compartment in which the fuel tank is situated.

(9) The means of control of a valve or cock referred to in subsection (8) shall consist of

(a) an extended spindle;

(b) a self-closing valve actuated by a trip wire; or

(c) any other suitable device.

(10) Where an aluminum fuel tank is fitted on a fishing vessel, all valves, fittings and piping fitted to the fuel tank shall be of a material compatible with aluminum.

- SOR/85-43, s. 2

- SOR/86-1025, s. 1(F)

- SOR/95-372, s. 7

11 Every fuel tank on a fishing vessel shall be securely chocked, fastened in place and electrically bonded to the vessel’s ground plate or to the engine.

- SOR/85-43, s. 2

12 Every fuel tank containing gasoline on a fishing vessel shall be situated remote from heated surfaces.

12.1 (1) Every permanent fuel tank on a fishing vessel shall be

(a) bonded electrically to the fuel piping system and engine; and

(b) installed and maintained so as to prevent fuel leakage.

(2) Every portable reserve fuel tank on a fishing vessel shall meet the requirements of the Canadian Standards Association standard, B376-M1980, Portable Containers for Gasoline and Other Petroleum Fuels, in force at the time of purchase of the portable reserve fuel tank and be stored as far as practicable from heat or ignition sources, propulsion machinery compartments and the crew’s quarters.

(3) Fuel tank filling arrangements on a fishing vessel shall be such as to prevent spillage into shipboard spaces, including bilges.

(4) Where a fuel tank is filled by means of a funnel, nozzle or similar device, continuous contact shall be maintained between the shipboard filling pipe and the filling device immediately prior to and during the entire fuelling operation.

(5) During a gasoline fuelling operation, every door, window and porthole on the fishing vessel shall be closed and all spark- or flame-producing equipment on the fishing vessel and in the vicinity of the fuelling operation shall be shut off.

- SOR/89-283, s. 4

12.2 Every inboard gasoline-fuelled engine on a fishing vessel shall

(a) be equipped to prevent fuel leakage into bilges or enclosed spaces;

(b) have a wire gauze-covered drip pan located below the carburetor;

(c) where the engine is located below deck or in an enclosure where fuel vapour will not readily dissipate, have an air intake arrangement that will arrest back-fire flame; and

(d) where the engine is located in a space required by subsection 12.3(2) to be mechanically ventilated, have a starting switch arrangement that will cause the ventilation fan to operate for a suitable period prior to engine ignition.

- SOR/89-283, s. 4

12.3 (1) Every space on a fishing vessel in which machinery is located shall be ventilated so that in all weather conditions where the engines and other fuel-burning appliances are operating at full power, an adequate supply of air is maintained to ensure the safety and comfort of the crew and the operation of the engines and appliances.

(2) A mechanical ventilation system shall be installed on a fishing vessel in accordance with subsection (3) in

(a) every space that is below deck and in which a gasoline-fuelled engine is located; and

(b) every other space, including bilges, in which gasoline fuel vapours may collect and may not readily dissipate.

(3) The mechanical ventilation system referred to in subsection (2) shall meet the following requirements:

(a) the system shall include both inlet and exhaust ducts;

(b) the exhaust duct opening shall be located in a low position in the space that permits the most efficient ventilation;

(c) the exhaust duct outlet shall lead to a location on the open deck where fumes may safely dissipate;

(d) the fan in the exhaust duct shall be spark proof; and

(e) where the fan motor is located in an area where ignitable vapours may be generated or collect, the fan motor shall be spark proof.

- SOR/89-283, s. 4

Exhaust Pipes

13 (1) Exhaust pipes from the main engines and from auxiliary engines of a fishing vessel shall be permanently mounted and shall lead to the open air outside the vessel through the uppermost deck or canopy or through the side.

(2) Where the exhaust pipes referred to in subsection (1) pass through the uppermost deck or canopy, they shall be of sufficient height to ensure that exhaust gases are prevented from escaping into the fishing vessel.

(3) Where the exhaust pipes referred to in subsection (1) pass through the side of a fishing vessel, the connection shall be watertight and provision shall be made to prevent the engine from being flooded.

(4) All exhaust pipes on a fishing vessel shall be well secured and be clear of all woodwork and other combustible materials and, where considered necessary by an inspector, they shall be covered with lagging.

Machinery Controls

14 (1) Means of stopping the propulsion of a fishing vessel, other than by shutting off a valve or cock fitted to the fuel tank, shall be provided outside the space where the machinery is located and such means shall be fire resistant.

(2) Subsection (1) does not apply to a fishing vessel the construction of which was commenced before June 1, 1974.

- SOR/82-633, s. 1

- SOR/95-372, s. 7(F)

Steering Gear

14.1 Where a manually operated hydraulic steering system is the auxiliary system to a powered hydraulic steering system, the change-over mechanism shall be located in the wheelhouse.

- SOR/82-129, s. 4

Underwater Fittings

15 (1) Valves or cocks shall be fitted to all suctions and discharges that pass through the hull of a fishing vessel below the weatherdeck.

(2) Subsection (1) does not apply to

(a) pump discharges of 38 mm or less in internal diameter that are situated above the load water line;

(b) keel cooling systems; or

(c) scuppers that pass from the weatherdeck to the ship’s side above the load water line.

(3) The cocks or valves required by subsection (1) shall be fitted as close to the side of the fishing vessel as possible.

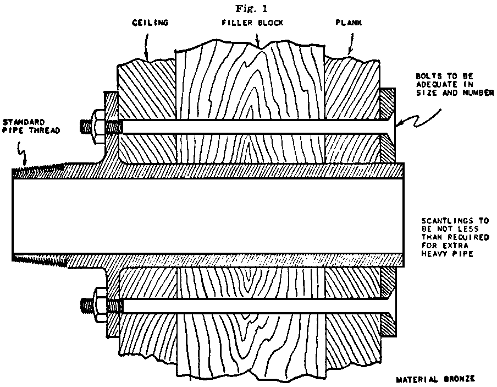

(4) Suction and discharge valves and cocks on a steel fishing vessel shall be attached to the plating of the hull or to the plating of fabricated water boxes by

(a) bolts with countersunk heads tapped through the plating, or

(b) studs that are screwed into heavy steel pads welded or riveted to the plating and that do not penetrate the plating,

and such valves or cocks shall be fitted with spigots passing through the plating.

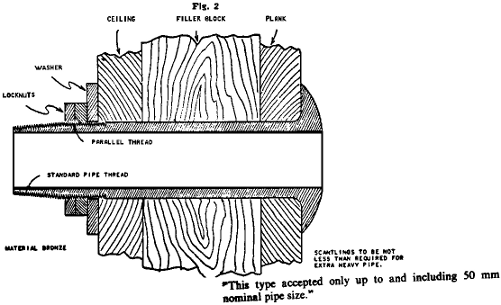

(5) Suction and discharge valves and cocks on a wooden fishing vessel shall be attached to the hull by the methods prescribed in Schedule VII or any other method accepted by the Board after full particulars have been submitted to it.

- SOR/95-372, s. 7(F)

Stern Bearings

16 Stern bearing assemblies of a fishing vessel shall consist of

(a) a stern bearing not less than 3 1/2 shaft diameters in length;

(b) a gland situated inside the vessel; and

(c) a watertight tube fitted between the bearing and the gland.

Rudder Stocks

17 On a fishing vessel, the diameter of rudder stocks for rudders fitted with bottom pintles shall not be less than

(a) as shown in the following table:

Length of ship in metres Diameter of rudder stock in millimetres 12 50 15 56 18 62 21 72 24 82; or (b) that calculated by the following formula:

D = 16.67 cubic root (A x R x V2)

where

- D =

- diameter of rudder stock in millimetres,

- A =

- total area of one face of rudder in square metres,

- R =

- average horizontal distance in metres between the trailing edge of rudder and the centre line of stock, and

- V =

- maximum speed of vessel in knots, or eight knots, whichever is the greater.

Shafting

18 (1) Subject to subsection (2), where the propulsion shafting of a fishing vessel is driven by a diesel or a gasoline engine, the intermediate shaft shall

(a) be made of material having a tensile strength of not less than 372 MPa; and

(b) have a diameter not less than that obtained by the following formula:

d = 106.41 cubic root (H/R) x [cubic root (414/S) or 0.85, whichever is the greater]

where

- d =

- diameter of the intermediate shaft in millimetres,

- H =

- brake kilowatt power of the engine at continuous rating,

- R =

- revolutions per minute of the intermediate shaft at continuous rating,

- S =

- tensile strength of the intermediate shaft material in megapascals.

(2) Where a fishing vessel is operated exclusively in fresh water, the diameter of the intermediate shaft may be 1.75 per cent less than the diameter obtained by the formula set out in subsection (1).

(3) Where the propulsion shafting of a fishing vessel is not driven by a diesel or gasoline engine, the size of the intermediate shaft shall be determined by the Board.

19 (1) Where the propulsion shafting of a fishing vessel is driven by a gasoline engine, the tailshaft shall

(a) be made of material having a tensile strength of not less than 372 MPa; and

(b) have a diameter not less than the diameter of the intermediate shaft, but in no case less than 28.5 mm.

(2) Where the propulsion shafting of a fishing vessel is driven by a diesel engine, the tailshaft shall

(a) be made of material having a tensile strength of not less than 372 MPa; and

(b) have a diameter not less than that obtained by the following formula, but in no case less than 32 mm:

D = 1.05 x 106.41 cubic root (H/R) x [cubic root (414/S) or 0.85, whichever is the greater] + (KP/C)

where

- D =

- diameter of the tailshaft in millimetres,

- H =

- brake kilowatt power of the engine at continuous rating,

- R =

- revolutions per minute of the intermediate shaft at continuous rating,

- S =

- tensile strength of the tailshaft material in megapascals,

- P =

- diameter of propeller in millimetres,

- K =

- 0.00079 P or 1, whichever is the smaller,

- C =

- 100 for a carbon steel shaft, and 144 for a shaft

(i) fitted with a continuous liner,

(ii) running in oil,

(iii) made of bronze, monel, stainless steel or other corrosion-resistant alloy, or

(iv) fitted with non-continuous liners, when the shaft is completely covered between such liners with rubber or neoprene that has been applied and bonded.

(3) Where a fishing vessel is operated exclusively in fresh water, the diameter of the tailshaft may be 1.75 per cent less than the diameter obtained by the formula set out in subsection (2).

(4) Where the propulsion shafting of a fishing vessel is not driven by a diesel or gasoline engine, the size of the tailshaft shall be determined by the Board.

- SOR/79-93, s. 1

20 (1) Subject to subsection (2), a certificate of test of the material used in the making of an intermediate shaft or tailshaft for a fishing vessel, which has been issued by the manufacturer of such material or by an inspector, shall be submitted by the owner of the fishing vessel to the steamship inspection office for the area in which the fishing vessel is being constructed.

(2) Subsection (1) does not apply to the owner of a fishing vessel that is powered with an engine that does not exceed 373 brake kW continuous rating.

- 1987, c. 7, s. 84(F)

Construction of Hulls

21 (1) Where the engine room and crew space of a fishing vessel exceeding 15.2 m but not exceeding 24.4 m in length are in adjoining compartments or are connected in any way, the bulkheads or decks between the engine room and the crew spaces shall be either

(a) watertight, or

(b) closely fitted to prevent fumes from the engine room entering the crew spaces,

and access openings in such bulkheads or decks shall be fitted with doors or covers of similar construction.

(2) Where, on a fishing vessel not exceeding 15.2 m in length,

(a) the engine room and the crew spaces are in adjoining compartments or connected in any way, or

(b) the crew spaces open to the engine room,

the inlet and outlet ventilation area required by section 22 shall each be increased by 2 000 mm2 for each member of the crew berthed in such compartment.

- SOR/95-372, s. 7(E)

22 (1) An engine room on a fishing vessel shall be provided with ventilators of a total cross-sectional area of not less than 16 000 mm2.

(2) Crew sleeping spaces on a fishing vessel shall be provided with inlet ventilators and exhaust ventilators of a sufficient size and number to ensure that the total inlet area and the total exhaust area are each not less than 2 000 mm2 for each berthed crew member.

23 (1) Scantling of hatch coamings, beams and covers of a fishing vessel shall not be less than is set forth in Schedule II.

(2) Hatchways on a fishing vessel shall be provided with efficient means for battening them down and making them watertight.

(3) Flush deck scuttles on a fishing vessel shall be watertight and strongly constructed of steel, bronze or aluminum and shall have effectively secured covers that are retained on hinges or by a chain permanently attached to the ship’s structure.

(4) Non-ferrous deck scuttles on a steel fishing vessel shall be isolated from the steel structure of the vessel.

- SOR/85-43, s. 3

- SOR/86-1025, s. 2(F)

- SOR/89-96, s. 1

24 (1) Subject to subsection (2), a fishing vessel shall be fitted with two main transverse watertight bulkheads, one located forward of amidships at a distance not exceeding 35 per cent of the length of the vessel and the other located aft of amidships at a distance not exceeding 45 per cent of the length of the vessel, and the construction of the bulkheads shall be in accordance with Schedule III.

(2) Subsection (1) does not apply in respect of

(a) a fishing vessel of open construction; or

(b) a fishing vessel operating in fresh water where the keel of the fishing vessel was laid prior to May 1, 1988.

- SOR/89-96, s. 2

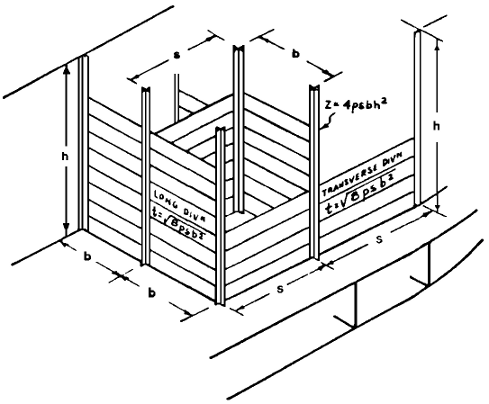

24.1 To control the movement of fish carried in bulk, every fishing vessel engaged in the carriage of herring or capelin in bulk shall be provided with both longitudinal and transverse portable fish hold divisions that meet the requirements set out in Schedule G.

- SOR/78-919, s. 1

24.2 Where a shaft tunnel access cover is fitted in a fish hold, it shall be fitted and secured in such a manner as to prevent dislodgment.

- SOR/78-919, s. 1

25 Stern posts and shaft logs on a fishing vessel shall be sufficiently large to enable tailshafts of diameters required by section 19 to be fitted without unduly weakening the structure.

26 (1) Subject to subsection (2), the sills of doors giving access to the main hull of a fishing vessel shall have a minimum height of 300 mm of which at least 230 mm shall be permanent and the remaining height of sill may be portable, if they are properly stowed in convenient positions.

(2) Where doors are situated on top of any superstructure, deck house or raised forecastle on a fishing vessel, the height of permanent sills shall be at least 150 mm.

27 (1) Where side scuttles are fitted below the weatherdeck of a fishing vessel, deadlights or plugs, attached by hinges or a chain, shall be provided adjacent to the scuttle.

(2) Where a fishing vessel proceeds more than 20 nautical miles from land and there is no method of preventing water from entering the main hull through a broken window or port light, storm shutters and deadlights respectively shall be fitted to those openings.

(3) Plate glass having a minimum thickness of 6 mm shall be fitted in the wheelhouse windows of

(a) all new fishing vessels; and

(b) new vessels when replacement of those windows becomes necessary.

(4) All doors giving access to the main hull of a fishing vessel shall be strongly constructed and hung on substantial hinges and locking arrangements shall be such that a door can be opened from either side.

(4.1) Subject to subsection (4.3), a fishing vessel shall have at least two means of escape, including the main entrance, in each crew space and area in which the crew may be normally employed.

(4.2) For the purposes of subsection (4.1), one of the means of escape shall be located as far as possible from the main entrance and may be a window or a scuttle that is of sufficient proportions to provide for easy exit by the crew members and that is capable of being retained in an open position while being used as an escape route.

(4.3) The requirements of subsections (4.1) and (4.2) do not apply

(a) in respect of a fishing vessel the keel of which was laid prior to May 1, 1988; or

(b) where, in the opinion of an inspector, a second means of escape is not practicable due to size limitations or spatial layout of a crew space or area in which the crew may be normally employed.

(5) Where entrance to the crew space on a fishing vessel is by way of the engine room, an escape hatch shall be fitted from the crew space to the open deck.

(6) Where exit from the crew space of a fishing vessel to the open deck is provided by one means only, it shall be of sufficient proportions to provide for easy exit for the number of men berthed and shall be as near the centre line of the ship as is practicable.

(7) Two engine room entrances providing easy access, each measuring at least 560 mm by 560 mm, shall be fitted on a fishing vessel unless this is not practicable, in which case one engine room entrance shall be fitted that is placed as near the centre line of the vessel as is practicable and that measures

(a) in the case of a vessel exceeding 15.2 m and not exceeding 24.4 m in length, at least 610 mm by 1 220 mm; and

(b) in the case of a vessel not exceeding 15.2 m in length, at least 610 mm by 915 mm.

- SOR/89-96, s. 3

- SOR/95-372, s. 7

28 (1) Subject to subsections (2) and (3), bulwark, rails, chains, wire rope or any combination of these shall be fitted around the weather deck of a fishing vessel at least 760 mm in height above the weatherdeck.

(2) An inspector may allow the bulwarks, rails, chains and wire rope referred to in subsection (1) to be portable or to be dispensed with, at his discretion, at places where, in his opinion, they would interfere with the fishing operations of the vessel.

(3) The bulwarks, rails, chains or wire rope referred to in subsection (1) may be less than 760 mm in height in way of deckhouses if suitable handrails are fitted on the sides of such deckhouses.

Stability

29 (1) Subject to subsection (8), an inclining experiment shall be conducted in the presence of and to the satisfaction of an inspector in respect of every fishing vessel on completion or near completion of

(a) its construction;

(b) its registration as a Canadian ship;

(c) its conversion to herring or capelin fishing; or

(d) its modification as described in paragraph 5(3)(d).

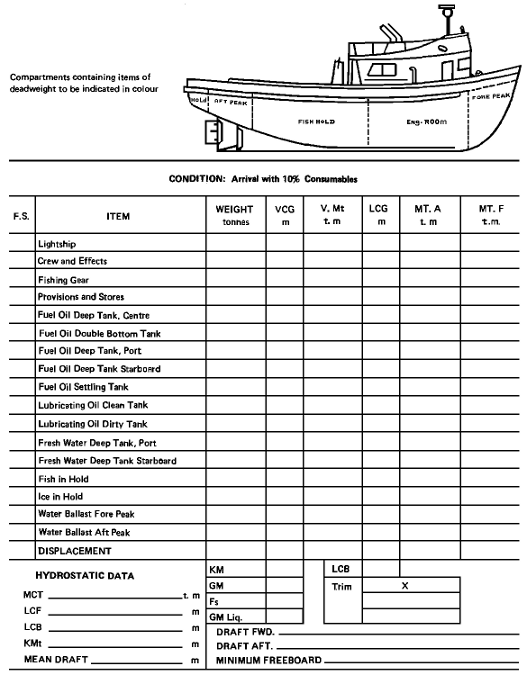

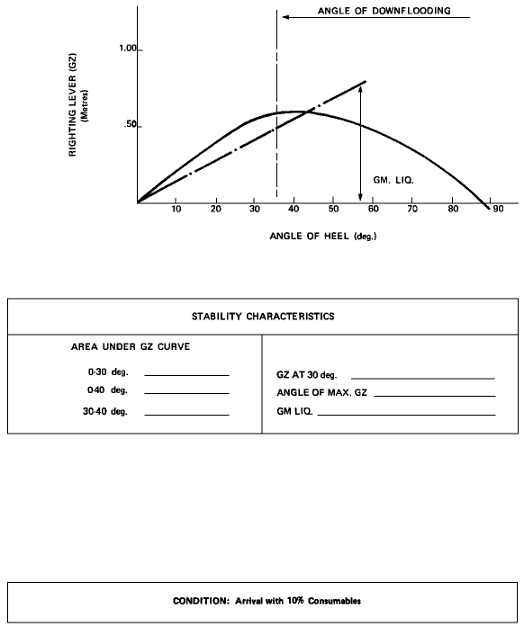

(2) Subject to subsection (3), the results obtained from the inclining experiment referred to in subsection (1) in respect of a fishing vessel shall be developed to indicate the stability of the vessel under the following conditions:

(a) lightship;

(b) port departure;

(c) arrival at fishing grounds;

(d) half load;

(e) full load;

(f) worst operating condition affecting the stability;

(g) worst operating with accumulated ice on topsides and rigging; and

(h) port, after discharge of cargo with 10 per cent fuel, fresh water and stores remaining and accumulated ice on topsides and rigging.

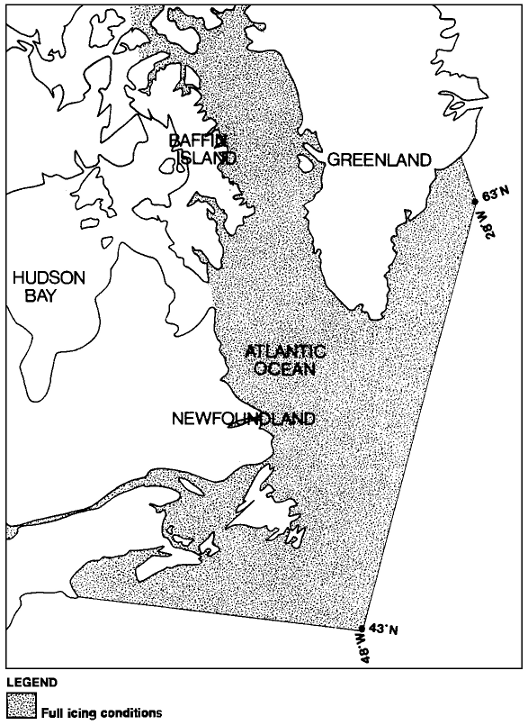

(3) The results obtained from the inclining experiment referred to in subsection (1) are not required to be developed to indicate the stability of a fishing vessel under conditions specified in paragraphs (2)(g) and (h) unless the vessel is to be operated in or transferred to any of the waters where vessels are subject to icing as set out in Schedule VI.

(4) For the purposes of subsection (2), an allowance shall be made if fish are stowed elsewhere than in the hold of a fishing vessel.

(5) For the purposes of paragraphs (2)(g) and (h), accumulated ice shall be regarded as weighing

(a) 54 kg/m2 of the total deck area, including the superstructure and deckhouse tops that are exposed to the weather;

(b) 37 kg/m2 of the area exposed to the weather in the case of the superstructure and deckhouse fronts, and the deckhouse sides and bulwarks including the area of the deckhouse sides and bulwarks on both sides of the vessel except that only the inboard surfaces shall be included in computing the bulwark areas;

(c) 78 kg/m2 of the area taking into consideration overall block dimensions, in the case of the guardrails and stanchions, hatch coamings, companionways and ship fittings exposed to the weather; and

(d) 48 kg per running metre in the case of rigging, masts, derricks and similar high objects measured to a height of 6.1 m above the main weather deck.

(6) For the purposes of paragraphs (2)(g) and (h), the position of the vertical centre of gravity of accumulated ice shall be determined using the masses calculated in accordance with subsection (5).

(6.1) [Repealed, SOR/79-905, s. 3]

(7) The owner of every fishing vessel shall ensure that a booklet is placed on board the vessel for the information of the master, which booklet shall

(a) indicate the stability characteristics of the vessel;

(b) contain appropriate information relative to loading under each of the conditions specified in subsection (2) for which results obtained from the inclining experiment have been developed; and

(c) consist of sheets for each condition specified in subsection (2), for which the results obtained from the inclining experiment have been developed, which sheets shall be similar to those shown in Schedule V.

(8) An inspector may dispense with the inclining experiment required by this section in respect of a fishing vessel, if,

(a) the requirements of this section have been met in respect of a sister vessel;

(b) the builder or owner thereof has supplied a letter certifying that the vessel and the sister vessel are identical in all respects; and

(c) the inspector has verified that the lightship displacement of the vessel is, as far as possible, the same as that of the sister vessel.

- SOR/78-496, s. 1(F)

- SOR/78-919, s. 2

- SOR/79-905, s. 3

- SOR/82-299, s. 2

29.1 (1) Subject to subsections (2) to (4), where bulwarks on weather parts of the working deck of a fishing vessel form wells, the minimum freeing port area, expressed in square metres, in respect of each such bulwark shall be not less than

(a) 0.7 + 0.035 l, where l is 20 m or less, and

(b) 0.07 l, where l exceeds 20 m,

where l, expressed in metres, is the lesser of the length of bulwark in the well and 70 per cent of the length of the vessel.

(2) Where the height of the bulwark in a well on the working deck is more than 1,200 mm, the minimum freeing port area shall be increased, for each 100 mm in excess of 1,200 mm, by 0.004 m2 per metre of length of well.

(3) Where the height of the bulwark in a well on the working deck is less than 900 mm, the minimum freeing port area may be decreased, for each 100 mm less than 900 mm, by 0.004 m2 per metre of length of well.

(4) Where the vessel’s sheer is such that the minimum freeing port areas, calculated in accordance with subsections (1) to (3), do not provide rapid and effective freeing of water from the deck, those areas shall be increased by such amount as will provide rapid and effective freeing of water from the deck.

(5) The freeing ports of every fishing vessel shall be arranged along the length of bulwarks so as to provide rapid and effective freeing of water from the deck of the vessel, and the lower edges of the freeing ports shall be as close to the deck as possible.

(6) On every fishing vessel, poundboards shall be stowed, and means of stowage of fishing gear shall be arranged, in such a manner that the effectiveness of the freeing ports of the vessel is not impaired.

(7) Every poundboard on a fishing vessel shall be so constructed that it can be secured in position when in use and will not hamper the rapid and effective freeing of water from the deck of the vessel.

(8) Every freeing port over 300 mm in depth of a fishing vessel, shall be fitted with bars spaced not more than 230 mm apart, or with other suitable protective devices.

(9) Where the protective devices fitted in accordance with subsection (8) are covers, they shall be of a construction approved by the Minister.

(10) In a fishing vessel intended to operate in areas subject to icing, protective devices fitted in accordance with subsection (8) shall be capable of being easily removed to restrict or reduce ice accretion.

- SOR/79-93, s. 2

- SOR/79-905, s. 4

Life Saving Equipment

30 (1) In this section and in section 31, approved, when used in reference to an article, means that the article has been built in accordance with the standards therefor in the Life Saving Equipment Regulations and has been approved by the Board.

(2) Every fishing vessel of open construction not exceeding 12.2 m in length shall carry

(a) one approved life jacket for each person on board; and

(b) one approved lifebuoy fitted with 27 mm of line.

(3) Every fishing vessel of closed construction not exceeding 12.2 m in length shall carry

(a) one approved lifejacket for each person on board the vessel;

(b) one approved lifebuoy fitted with 27 m of line;

(c) subject to paragraph (d), and if the vessel is subject to inspection, a boat, dory or skiff capable of accommodating all persons on board or a life raft capable of accommodating all persons on board or four persons, whichever is the greater;

(d) if making home-trade voyages, Class IV, or minor waters voyages, Class II, and the vessel is subject to inspection, a boat, dory or skiff capable of accommodating all persons on board, or a life raft, with or without canopy, capable of accommodating three persons.

(4) Every fishing vessel exceeding 12.2 m in length shall carry

(a) one approved lifejacket for each person on board the vessel;

(b) two approved lifebuoys, one fitted with 27 m of line and the other with an approved lifebuoy light;

(c) in the case of a vessel the keel of which was laid on or after January 6, 1965,

(i) a boat, dory or skiff capable of accommodating not less than four persons,

(ii) a life raft of sufficient capacity to accommodate

(A) 50 per cent of the persons on board, or

(B) if the vessel makes voyages other than inland voyages and goes beyond the limits of home-trade Class III voyages, 75 per cent of the persons on board, and

(iii) if the equipment required by subparagraphs (i) and (ii) is not capable of accommodating 1 1/2 times the number of persons on board, such additional boats, dories, skiffs or life rafts as are necessary to provide accommodation in the aggregate for 1 1/2 times the number of persons on board; and

(d) in the case of a vessel the keel of which was laid before January 6, 1965,

(i) the equipment described in paragraph (c),

(ii) a boat, dory or skiff capable of accommodating not less than four persons together with life rafts capable of accommodating all persons on board, or

(iii) a sufficient number of lifeboats, boats, dories or skiffs capable of accommodating all persons on board, except that a vessel equipped in accordance with this subparagraph that makes other than inland voyages and goes beyond the limits of home-trade, Class III voyages shall, carry a life raft of sufficient capacity to accommodate 75 per cent of the persons on board in addition to the equipment already carried.

(5) Where

(a) a vessel does not go beyond the limits of

(i) a home-trade voyage, Class III, or

(ii) an inland voyage, and

(b) the crew of the vessel does not exceed four persons,

a life raft capable of accommodating not less than four persons may be carried by the vessel in lieu of the equipment required by paragraph (4)(c) or (d).

(6) The weight of each seine skiff carried on board a fishing vessel shall be both established and certified to the satisfaction of an Inspector who shall then cause the following details to be marked on the stem or sheer strake thereof, in permanent characters, clearly visible and as near as possible to 75 mm in height:

(a) the operating weight of the skiff measured in tons, when it is fully equipped with fuel and its fresh water tanks are full;

(b) the date on which the measurement is taken; and

(c) the Inspector’s initials.

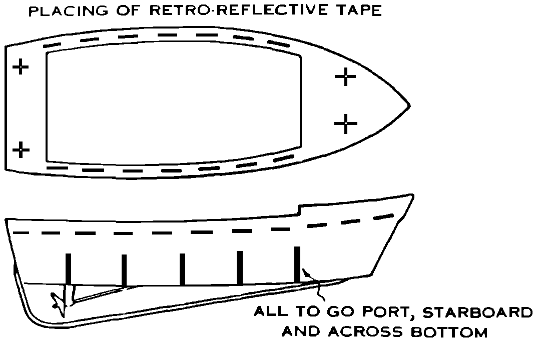

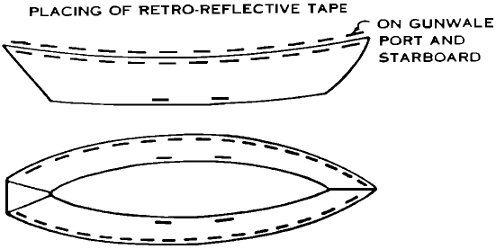

(7) Every skiff, seine skiff and dory used as life-saving equipment on board a fishing vessel shall be marked with retro-reflective tape in the manner required by Schedule V to the Life Saving Equipment Regulations as illustrated in Figures 1 and 2 of Schedule IX.

- SOR/78-919, s. 3

- SOR/79-905, s. 5

- SOR/96-217, s. 6

31 The number of persons that one lifeboat, boat, dory or skiff shall be deemed capable of carrying shall be determined

(a) in the case of an approved lifeboat or approved boat, in accordance with the Life Saving Equipment Regulations;

(b) in the case of a seine skiff of normal construction built in accordance with plans accepted by the Board and fitted with internal buoyancy appliances of 0.0283 m3 standard unit of capacity per person, in accordance with the following formula:

N = (L x B x D) ÷ 0.566

where

- N =

- number of persons,

- L =

- overall length in metres,

- B =

- maximum breadth in metres, at level of gunwale, to outside of plank, and

- D =

- the least vertical distance in metres measured from the top of the keel to the top of the gunwale or from the top of the keel to the lowest point of the transom, whichever is the smaller dimension;

(c) in the case of seine skiffs of heavy construction that are built in accordance with plans accepted by the Board and are not fitted with internal buoyancy appliances, by the Board;

(d) in the case of dories, in accordance with the following table:

Overall length of dory in metres Maximum number of persons 3.7 3 4.3 4 4.6 4 4.9 5 5.2 5 5.5 6 5.8 6; and (e) in the case of boats or skiffs other than those described in paragraph (a), (b) or (c), in accordance with the following formula:

N = (L × B × D) ÷ 0.75

where

- N =

- number of persons,

- L =

- overall length in metres,

- B =

- maximum breadth in metres, at level of gunwale, to outside of plank, and

- D =

- the east vertical distance in metres measured from the top of the keel to the top of the gunwale or from the top of the keel to the lowest point of the transom, whichever is the smaller dimension.

32 Every fishing vessel exceeding 12.2 m in length shall carry the following equipment for each lifeboat, boat, dory or skiff provided in compliance with these Regulations, and such equipment shall be kept readily available to place in the lifeboat, boat, dory or skiff in case of emergency:

(a) one full bank of oars and a complete set of rowlocks or thole pins;

(b) where the vessel operates in salt water, one suitable container holding at least 1 L of fresh water for each person the boat is deemed capable of carrying;

(c) one watertight can containing 12 approved self-igniting red flares;

(d) one bucket and one bailer;

(e) two sheath knives or hatchets, except that in a dory only one sheath knife or hatchet is required;

(f) one boat hook or fishing gaff;

(g) one storm lantern with sufficient oil to burn for at least seven hours, and a watertight can of matches;

(h) one painter attached to bows of boat;

(i) one dory compass; and

(j) one sea anchor, except in the case of a dory.

- SOR/78-919, s. 4

33 (1) Except as otherwise specified in Schedule IV, every life raft of every vessel making foreign, home-trade Class I or home-trade Class II voyages shall carry all the equipment set out in items 1 to 24 of that Schedule, which equipment shall be known as Class A equipment.

(2) Except as otherwise specified in Schedule IV, every life raft of every vessel making home-trade Class III, inland waters Class I, inland waters Class II or minor waters Class I voyages shall carry all the equipment set out in items 1 to 13 of that Schedule, which equipment shall be known as Class B equipment.

(3) Every life raft of every vessel making voyages other than those described in subsections (1) and (2) shall carry a knife, two paddles and a heaving line with quoit.

- SOR/95-372, s. 7(E)

34 Where the lifeboats, boats, dories or skiffs on a fishing vessel are of such size or are so stowed that they cannot be launched by hand, means for launching shall be provided to the satisfaction of an inspector.

SARTs

34.1 (1) A fishing vessel that is 20 m or more in length and is engaged on a foreign voyage or a home-trade voyage, Class I, shall carry a SART stowed so that it is readily accessible for immediate use and for placing in one of the survival craft that are launched first.

(2) A SART carried on a fishing vessel shall meet the requirements of sections 28 and 29 of the Ship Station (Radio) Technical Regulations, 1999.

(3) Every radio operator of a fishing vessel that carries a SART shall comply with the requirements of subsection 49(2) of the Ship Station (Radio) Technical Regulations, 1999.

(4) Despite subsection (1), a fishing vessel that on March 31, 2001 was required by these Regulations to carry two Class II EPIRBs may continue to carry them instead of a SART until one of the batteries of the Class II EPIRBs needs to be replaced if

(a) the Class II EPIRBs meet the requirements of sections 25 to 27 of the Ship Station (Radio) Technical Regulations, 1999; and

(b) the radio operator complies with the requirements of subsection 49(1) of the Ship Station (Radio) Technical Regulations, 1999.

- SOR/96-217, s. 2

- SOR/2000-262, s. 2

Fire Extinguishing Equipment

35 (1) Every fishing vessel fitted with internal combustion propelling machinery shall be provided with fire extinguishers as set out in the table to this subsection but equivalent extinguishers as set out in section 36 may be used:

TABLE

Length of vessel Fire extinguishers 1 Not exceeding 12.2 m if of closed construction 4.5 L foam 2 Exceeding 12.2 m and not exceeding 19.8 m one 9 L foam and one 4.5 L foam 3 Exceeding 19.8 m and not exceeding 24.4 m two 9 L foam. (2) Every fishing vessel in which the propelling machinery includes an oil-fired boiler shall be provided in the boiler room with the following fire extinguishers as set forth in the table to this subsection but equivalent fire extinguishers as set forth in section 36 may be used:

TABLE

Length of vessel Fire extinguisher 1 Not exceeding 15.2 m one 9 L foam and one box of sand with scoop 2 Exceeding 15.2 m and not exceeding 24.4 m two 9 L foam and one box of sand with scoop. (3) Every fishing vessel fitted with cooking or heating appliances that burn liquid or gaseous fuel shall, in addition to the extinguishers mentioned in subsections (1) and (2), be provided with one 4.5 L foam fire extinguisher or one equivalent fire extinguisher as set forth in section 36.

36 (1) Every fire extinguisher required by these Regulations shall be of a type approved by

(a) the Underwriters’ Laboratories of Canada;

(b) the Department of Trade and Industry of Great Britain;

(c) the United States Coast Guard; or

(d) the Board.

(2) For the purposes of section 35, a carbon dioxide or dry chemical fire extinguisher is equivalent to a foam fire extinguisher if it has the capacity set out opposite the foam fire extinguisher capacity in the table to this subsection.

TABLE

Item Foam CO2 Dry Chemical Litres Kilograms Kilograms 1 4.5 2.25 1 2 9 4.5 2.25 (3) Fire extinguishers required by these Regulations shall, where possible, be stowed near the entrance to the space where they are intended to be used.

(4) Fire extinguishers in which the extinguishing medium is stored under pressure shall not be located in any crew living quarters on a fishing vessel.

(5) Every fire extinguisher provided in compliance with these Regulations shall be kept fully charged at all times; carbon dioxide gas in steel bottles shall be renewed whenever the loss of gas exceeds 10 per cent of the original charge as stamped on the bottle.

(6) Notwithstanding anything contained in these Regulations, the use of a vaporizing liquid fire extinguisher is prohibited, except that in radio rooms and at switchboards such an extinguisher may be used if it contains not more than 1.136 L of vapourizing liquid and is used in addition to the other extinguishers required by these Regulations.

(7) Fire extinguishers containing chlorobromomethane may be accepted as the equivalent of carbon tetrachloride fire extinguishers if they comply with the requirements of subsections (6) and (8).

(8) A notice shall be posted on or adjacent to any carbon tetrachloride fire extinguisher indicating that if the extinguisher is used for extinguishing fire in a confined space dangerous fumes will be given off which must not be inhaled.

- SOR/95-372, s. 7(E)

37 Every fishing vessel shall be equipped with fire buckets according to the following table:

| Length of vessel | Number of buckets |

|---|---|

| Not exceeding 12.2 m if of open construction | one |

| Not exceeding 12.2 m if of closed construction | two |

| Exceeding 12.2 m and not exceeding 19.8 m | three |

| Exceeding 19.8 m and not exceeding 24.4 m | four |

38 (1) Every fishing vessel exceeding 12.2 m in length shall be equipped with at least one hand or engine driven pump and apparatus whereby a suitable jet of water can be directed into any part of the ship.

(2) The internal diameter of the pipes for the pump mentioned in subsection (1) shall be not less than 19 mm.

(3) Subject to subsection (4), bilge pumps on a fishing vessel may be used as fire pumps by using them to pump sea water on deck.

(4) Where two bilge pumps are required on a fishing vessel, neither pump shall be used to pump sea water on deck unless it is possible for one bilge pump to pump bilge water overboard while the other pumps sea water on deck.

(5) Subject to subsection (6), the piping for a fire pump on a fishing vessel shall be of steel, bronze or other material that, in the opinion of the Board, is suitable for the purpose, and the joints for such piping shall be flanged or screwed.

(6) Where it is necessary to reduce the effect of vibration, short lengths of rubber or plastic hose may be installed and shall

(a) be clearly visible at all times;

(b) be of sufficient strength to withstand collapsing due to suction; and

(c) have joints made with clamps suitable for the purpose.

- SOR/95-372, s. 7(E)

39 (1) Appliances that are installed on a fishing vessel and that burn liquid or gaseous fuel shall be so fitted that there is a free circulation of air all around and below the appliance.

(2) Wooden bulkheads behind cooking or heating appliances on a fishing vessel shall be insulated where it is considered necessary by an inspector.

(3) Every fishing vessel of not more than 24.4 m in length that is provided with a liquefied petroleum gas installation shall comply with the requirements of the Marine Machinery Regulations for such vessels.

- SOR/83-272, s. 1

- SOR/95-372, s. 7

Lights and Signals

40 (1) The types of distress signals referred to in this section are the types of distress signals described in Schedule III to the Life Saving Equipment Regulations.

(2) Every fishing vessel shall carry 12 Type C distress signals and

(a) if operating more than 20 nautical miles from shore, six Type A distress signals;

(b) if operating not more than 20 nautical miles from shore, six Type B distress signals.

(3) Every fishing vessel shall carry sufficient lights and equipment to comply with the Collision Regulations.

- SOR/79-93, s. 3

- SOR/84-376, s. 1

Navigating Equipment

41 Every fishing vessel shall be provided with an efficient and suitable compass capable of being illuminated.

42 Every fishing vessel shall be provided with a 3 kg weight and 27 m of light line for sounding purposes.

Anchor and Cables

43 (1) Subject to this section, every fishing vessel shall carry a total anchor weight of not less than that derived from the following formulae:

(a) for cubic number up to 566

W = 0.64 CN, and

(b) for cubic number over 566

W = 0.48 CN + 91

where

(c) W = total anchor weight in kilograms,

(d) CN = cubic number (L x B x D),

(e) L = length of vessel in metres,

(f) B = greatest breadth of vessel in metres, measured to the inside of planking or plating, and

(g) D = the depth of the vessel in metres, measured at amidships from the top of keel to the top of the deck beam at side except that, in the case of a vessel that has a raised deck aft that extends forward of amidships, the depth D shall be measured to the line of that deck and, in the case of an open construction vessel, the depth D shall be measured to the top of the gunwale.

(2) Where approved patent anchors are adopted, 40 per cent of the total anchor weight shall be deducted, but the length and size of the anchor cable shall be based on the normal anchor weight.

(3) Where “W” is not more than 135 kg or 80 kg in the case of patent anchors, one or two anchors may be carried.

(4) Where “W” is more than 135 kg or 80 kg in the case of patent anchors, two anchors shall be carried.

(5) Where two anchors are carried, the weight of the main anchor shall be not less than 60 per cent of “W” and that of the second anchor shall be not less than 40 per cent of “W”.

(6) Trawl boards or scallop nets used in normal fishing operations may be used on a fishing vessel in lieu of anchors if they do not weigh less than the required total weight and in such case the trawl board or scallop net cable used may be accepted in lieu of the anchor cable required by subsection (8).

(7) A windlass or winch shall be provided on a fishing vessel that carries an anchor weighing more than 70 kg or if a winch normally used for fishing operations can be used, it may be accepted in lieu of an anchor windlass.

(8) Subject to subsection (6), an anchor cable of link chain, wire rope, manilla rope or other rope of a material of equal or greater strength than manilla hemp shall be carried in accordance with the following table:

Weight of main anchor in kilograms i.e. at least 60 per cent of “W” Minimum diameter of link chain or wire rope in millimetres Minimum circumference of manilla or other rope in millimetres Total length of cable in metres 1 or 2 anchors 45 9.5 64 Footnote for * 55 1 or 2 anchors 90 12.5 89 Footnote for * 55 1 or 2 anchors 135 14.0 102 82 2 anchors 180 16.0 114 100 2 anchors 230 17.5 127 137 2 anchors 270 19.0 127 137 Return to footnote *If two anchors are carried, the total length of cable shall be increased to 82 m.

- SOR/82-299, s. 3

Emergency Electrical Lighting

43.1 (1) Every fishing vessel other than one certified to operate only between sunrise and sunset shall be fitted with permanent or portable lights that will illuminate the launching stations and stowage position of all survival craft for at least one hour.

(2) Where non-rechargeable battery-operated hand lanterns are provided pursuant to subsection (1), the batteries shall be changed annually.

- SOR/81-199, s. 1

- SOR/96-217, s. 3(F)

First Inspection of New Construction

44 (1) Every fishing vessel shall be inspected during construction at such times as the inspector deems advisable.

(2) The owner of a fishing vessel shall notify the inspector at least one week in advance of

(a) the commencement of framing;

(b) the commencement of planking or plating;

(c) the launching; and

(d) the dock and sea trials.

(3) An inspector may, during inspection of new construction of a fishing vessel, approve any machinery or any electrical installation, equipment or appliance, without requiring it to be opened for inspection, if

(a) plans in respect of the machinery or the electrical installation, equipment or appliance are not required to be submitted under these Regulations; and

(b) the inspector is satisfied that the machinery or electrical installation, equipment or appliance is safe and suitable for the purpose for which it is intended.

(4) Inspection and construction of boilers, steam pipes, boiler mountings and air receivers of fishing vessels for which plans are required to be submitted under these Regulations shall be in accordance with the Marine Machinery Regulations.

(5) Dock trials and sea trials of a fishing vessel shall be held in the presence of an inspector, at which time the speed of the vessel, in knots, shall be estimated, the bilge and fire pumps and the steering and stopping powers of the vessel shall be tested, the launching arrangements for the life boats, boats, dories or skiffs shall be carried out, and any further tests shall be carried out that the inspector considers necessary to satisfy himself that the vessel is safe and suitable for the purpose for which it is intended.

- SOR/81-199, s. 2

- SOR/95-372, s. 7

Electrical Equipment, Installations and Appliances

44.1 (1) Subject to subsection (1.3), where the construction of a fishing vessel begins after April 27, 1996, the electrical equipment, installations and appliances on the fishing vessel shall be constructed in accordance with TP 127 as it reads on the day the construction begins.

(1.1) Before the construction, reconstruction or modification of a fishing vessel begins, the owner of the fishing vessel shall submit to the Board for inspection, in respect of the fishing vessel, the drawings, data and plans referred to in section 36 of TP 127.

(1.2) Subject to subsection (1.3), any substantial reconstruction or modification of the electrical equipment, installations or appliances on a fishing vessel shall, insofar as it is practicable, bring the electrical equipment, installations or appliances into compliance with TP 127 as it reads on the day the reconstruction or modification begins.

(1.3) Where TP 127 does not set out a standard in respect of a particular piece of electrical equipment or a particular electrical installation or appliance, the electrical equipment, installation or appliance shall be safe and effectively fulfil the purpose for which it is intended.

- SOR/81-199, s. 3

- SOR/83-706, s. 1

- SOR/96-217, s. 4

Periodic Inspection

45 Every fishing vessel propelled by steam shall have the following parts inspected annually by an inspector:

(a) boilers, boiler mountings and steam pipes;

(b) life-saving equipment; and

(c) fire-extinguishing equipment.

46 (1) Subject to subsection (2), every fishing vessel shall be inspected once every four years as follows:

(a) air receivers shall be tested by hydraulic pressure to 1 1/2 times the working pressure but the inspector may waive that test if the air receiver has a manhole or other opening that permits a thorough examination of the interior and he is satisfied that it is in a safe and sound condition;

(b) an engine trial shall be held and if the engine is found in good operating condition the inspector may accept it without opening it up for inspection, but where the running trial is not to the satisfaction of the inspector he may require that the engine, or any part thereof, be opened up for inspection;

(c) when the engine is opened up for overhaul, the owner shall notify the inspector so the inspector may have an opportunity to examine the engine;

(d) the hull shall be examined inside and out by the inspector while the vessel is in dry dock or while it is beached;

(e) fire and bilge pumps shall be tested by trial and overhauled if necessary;

(f) the rudder shall be examined in place, the weardown of the tailshaft measured and all sea connections opened up for inspection;

(g) all life-saving, fire-extinguishing and navigating equipment shall be inspected;

(g.1) the electrical equipment, installations and appliances on a fishing vessel shall be inspected in accordance with TP 127 as it reads on the day on which the inspection is made;

(h) tailshafts shall be inspected in accordance with section 47; and

(i) air compressor relief valves and air receiver relief valves shall be set to blow off at the assigned working pressure.

(2) The periodic inspection required by paragraph (1)(a) in respect of a new air receiver shall commence eight years after the date of the first inspection of the air receiver.

- SOR/81-199, s. 4

- SOR/96-217, s. 5

47 Tailshafts of a fishing vessel shall be inspected as follows:

(a) carbon steel tailshafts, where used in salt water, shall be completely withdrawn for inspection and the propeller removed at least once every four years;

(b) when the owner of a fishing vessel has, for any purpose, caused the tailshafts referred to in paragraph (a) to be withdrawn, he shall, in order to facilitate the inspection required by paragraph (a), notify the inspector that the tailshafts have been withdrawn and the propellor removed;

(c) bronze, monel, stainless steel or other non-corrosive tailshafts used in salt or fresh water and carbon steel tailshafts used in fresh water shall, if considered necessary by the inspector, be partially or completely withdrawn for inspection once every four years and the propellor shall, if considered necessary by the inspector, be removed once every four years; and

(d) when the owner of a fishing vessel has, for any purpose, caused the tailshafts referred to in paragraph (c) to be withdrawn, he shall, in order to facilitate the inspection referred to in paragraph (c), notify the inspector that the tailshafts have been withdrawn.

48 An inspector may, in addition to any inspection or test required by these Regulations, conduct any inspection or require any test to be made to satisfy himself that anything on a fishing vessel that may affect its seaworthiness is safe and suitable for the purpose for which it is intended.

49 (1) Notwithstanding the requirements for periodic inspection prescribed in this Part, an inspector may issue or extend an inspection certificate for a period not exceeding

(a) two months beyond the due date of periodic inspection; or

(b) five months beyond the due date of periodic inspection, if authorized to do so by the Divisional Supervisor.

(2) Prior to issuing or extending an inspection certificate under this section, the inspector shall, from such inspection of the hull, machinery and equipment, including the electrical installations, equipment and appliances, as is possible while the vessel is afloat, and without opening up any machinery except boilers and boiler mountings, satisfy himself that the fishing vessel is in a seaworthy condition.

(3) An inspection certificate issued or extended to the maximum period allowed under this section shall not be renewed or further extended without the permission of the Board.

- SOR/81-199, s. 5

- 1987, c. 7, s. 84(F)

50 Any alterations affecting the seaworthiness of a fishing vessel shall be equivalent to the standards of these Regulations and to the satisfaction of an inspector.

Duty of Master

51 The master of a fishing vessel shall take adequate steps to ensure that the crew understands the use of the life-saving and fire-extinguishing appliances and knows where they are located.

PART IIFishing Vessels Not Exceeding 15 Tons, Gross Tonnage

Application

52 This Part applies to fishing vessels not exceeding 15 tons, gross tonnage, that are not sailing ships.

Life Saving Equipment, Lights and Signals

53 (1) In this section, approved, when used in reference to an article, means that the article has been built in accordance with the standards therefor in the Life Saving Equipment Regulations and has been approved by the Board.

(2) Every fishing vessel not exceeding 12.2 m in length shall carry

(a) one approved life jacket for each person on board;

(b) one approved lifebuoy fitted with 27 m of line; and

(c) one watertight can containing six approved self-igniting flares.

(3) Every fishing vessel exceeding 12.2 m in length shall carry

(a) one approved life jacket for each person on board;

(b) a sufficient number of lifeboats, boats, dories, skiffs or seine skiffs to accommodate all persons on board the vessel; and

(c) one watertight can containing six approved self-igniting red flares.

(4) Every fishing vessel shall carry sufficient lights and equipment to comply with the Collision Regulations, and such lights shall be oil or electric.

(5) to (7) [Repealed, SOR/78-919, s. 5]

- SOR/78-919, s. 5

- SOR/84-376, s. 2

Fire Extinguishing Equipment

54 (1) Every fishing vessel of open construction shall carry one fire bucket.

(2) Every fishing vessel of closed construction shall carry

(a) one 4.5 L foam fire extinguisher or one equivalent fire extinguisher as set out in section 55;

(b) one fire bucket; and

(c) if fitted with cooking or heating appliances that burn liquid or gaseous fuel, one 4.5 L foam fire extinguisher, or one equivalent fire extinguisher, as set out in section 55, in addition to the fire extinguisher required under paragraph (a).

(3) In the case of a fishing vessel not exceeding five tons, gross tonnage, the equipment referred to in paragraphs (2)(b) and (c) need not be carried.

55 (1) Every fire extinguisher required by these Regulations shall be of a type approved by

(a) the Underwriters’ Laboratories of Canada;

(b) the Department of Trade and Industry of Great Britain;

(c) the United States Coast Guard; or

(d) the Board.

(2) For the purposes of section 54, a carbon dioxide or dry chemical fire extinguisher is equivalent to a foam fire extinguisher if it has the capacity set out opposite the foam fire extinguisher capacity in the table to this subsection.

TABLE

Item Foam CO2 Dry Chemical litres kilograms kilograms 1 4.5 2.25 1 2 9 4.5 2.25 (3) Fire extinguishers required by these Regulations shall, where possible, be stowed near the entrance to the space where they are intended to be used.

(4) Fire extinguishers in which the extinguishing medium is stored under pressure shall not be located in any crew living quarters on a fishing vessel.

(5) Every fire extinguisher provided in compliance with these Regulations shall be kept fully charged at all times; carbon dioxide gas in steel bottles shall be renewed whenever the loss of gas exceeds 10 per cent of the original charge as stamped on the bottle.

(6) Notwithstanding anything contained in these Regulations, the use of a vapourizing liquid fire extinguisher is prohibited, except that in radio rooms and at switchboards such an extinguisher may be used if it contains not more than 1.136 L of vapourizing liquid and is used in addition to the other extinguishers required by these Regulations.

(7) Fire extinguishers containing chlorobromomethane may be accepted as the equivalent of carbon tetrachloride fire extinguishers if they comply with the requirements of subsections (6) and (8).

(8) A notice shall be posted on or adjacent to any carbon tetrachloride fire extinguisher indicating that if the extinguisher is used for extinguishing fire in a confined space dangerous fumes will be given off which must not be inhaled.

- SOR/95-372, s. 7(F)

Precautions Against Fire

56 (1) Every permanent fuel tank on a fishing vessel shall be

(a) bonded electrically to the fuel piping system and engine; and

(b) installed and maintained so as to prevent fuel leakage.

(2) Every portable reserve fuel tank on a fishing vessel shall meet the requirements of Canadian Standards Association standard, B376-M1980, Portable Containers for Gasoline and Other Petroleum Fuels, in force at the time of purchase of the portable reserve fuel tank and be stored as far as practicable from heat or ignition sources, propulsion machinery compartments and crew’s quarters.

(3) Fuel tank filling arrangements on a fishing vessel shall be such as to prevent spillage into shipboard spaces, including bilges.

(4) Where a fuel tank is fuelled by means of a funnel, nozzle or similar device, continuous contact shall be maintained between the shipboard filling pipe and the filling device immediately prior to and during the entire fuelling operation.

(5) During a gasoline fuelling operation, every door, window and porthole on the fishing vessel shall be closed and all spark- or flame-producing equipment on the fishing vessel and in the vicinity of the fuelling operation shall be shut off.

(6) Every inboard gasoline-fuelled engine on a fishing vessel shall

(a) be equipped to prevent fuel leakage into bilges or enclosed spaces;

(b) have a wire gauze-covered drip pan located below the carburetor;

(c) where the engine is located below deck or in an enclosure where fuel vapour will not readily dissipate, have an air intake arrangement that will arrest back-fire flame; and

(d) where the engine is located in a space required by subsection (8) to be mechanically ventilated, have a starting switch arrangement that will cause the ventilation fan to operate for a suitable period prior to engine ignition.